Case study

Pro Light: when automation is illuminating

Story courtesy of A. Ariu and G. Mazzola/Lamiera

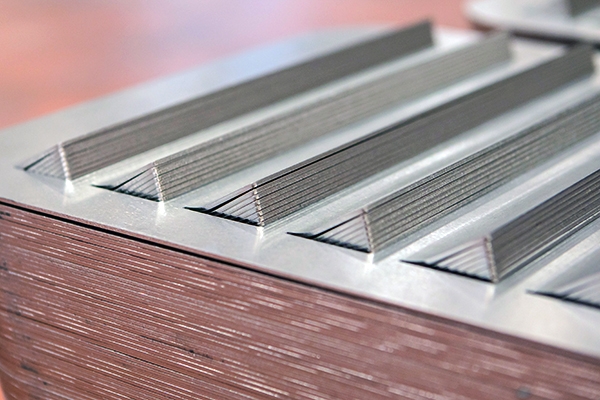

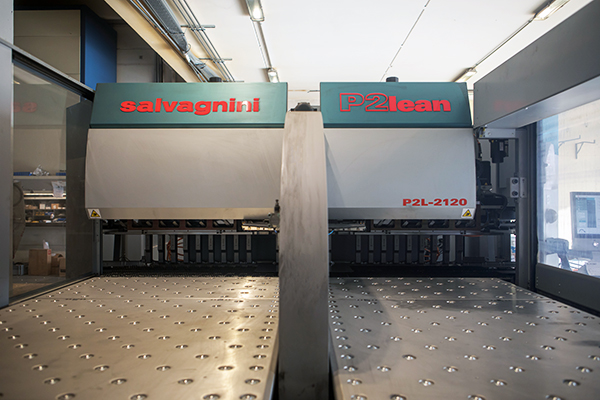

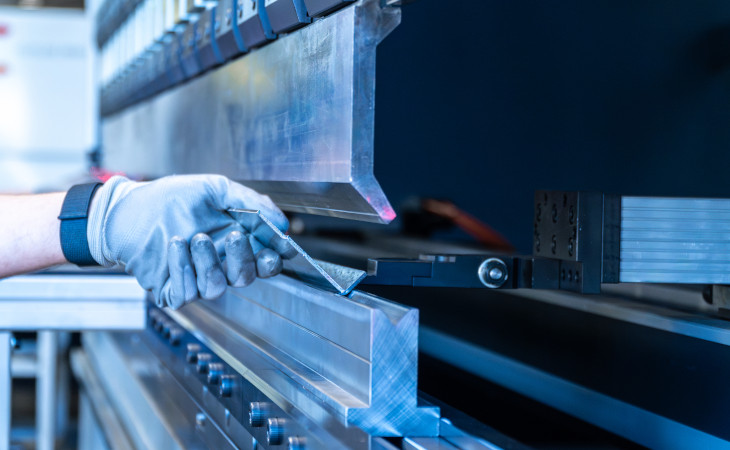

To develop its lighting systems, Pro Light relies on Salvagnini’s high-performance bending technologies, which are ideal for optimizing operational flows and increasing process efficiency in line with production needs.

When automation is illuminating

Highlights

- Pro Light

Working on the market for over twenty years, Pro Light was founded in 2000 and began operating immediately in the lighting industry, first as a retailer and then, a few years later, launching its own production of civil and industrial outdoor solutions. - The scenario

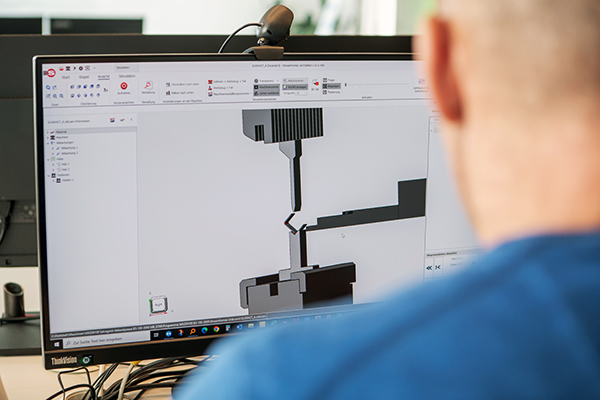

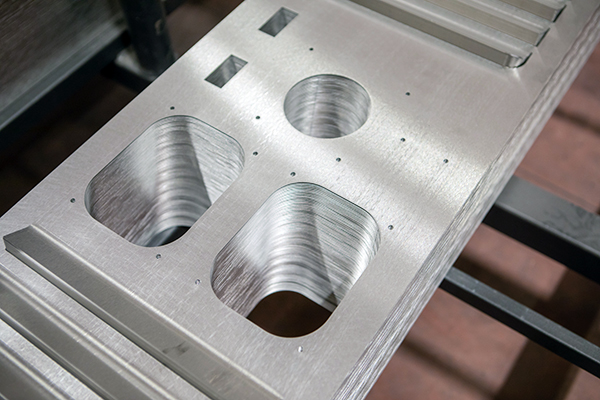

Pro Light manages the whole product development cycle in-house, from design to prototype production, to the first sample, and on to series production. The process starts with an idea, a metal sheet, and ends up with a finished product, complete with all the electronic parts, ready for installation. Every design is customized to meet precise specifications, but can also be the basis for the development of new ideas and new products. - The project

In 2022 Pro Light added fleet three Salvagnini B3 press brakes to its machinery - two of which featuring AU-TO, the automatic tool change device. With this investment, not only has the company achieved greater production process efficiency, but it has provided its staff with simple and easy-to-use, reliable, and obviously productive systems. - The outcome

For Pro Light automation is key to success, as well as the fundamental lever for increasing competitive performance and productivity.