Case study

Just-in-time kit production enabled by a high level of automation and smart technology

Story and pictures courtesy of Tidningen Maskinoperatören

Revent International AB in Upplands Väsby is responding to rising global demand for its rack ovens with the largest investment in the company’s history: entering the world of panel bending and making a step-change in machinery and technology through an investment in a Salvagnini Smart Factory.

The facility you see today, installed in our new 1,400 sqm production hall, offers a real sense of the future. A lot has happened since then, and what started as a refurbished barn has evolved into our fully renovated headquarters and factory.

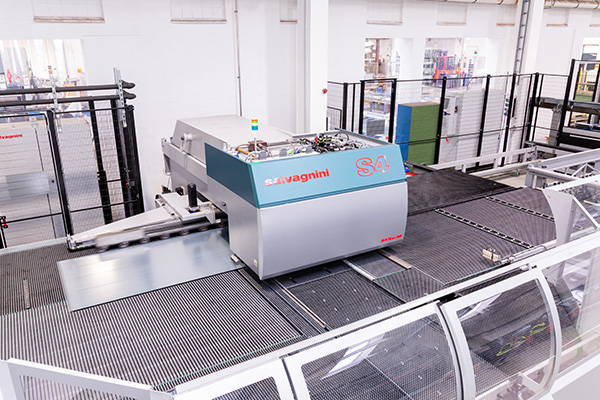

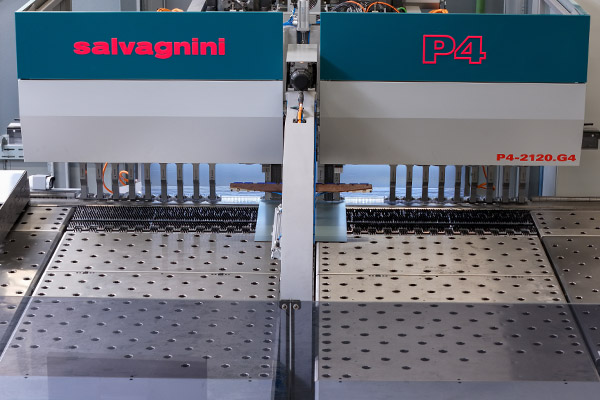

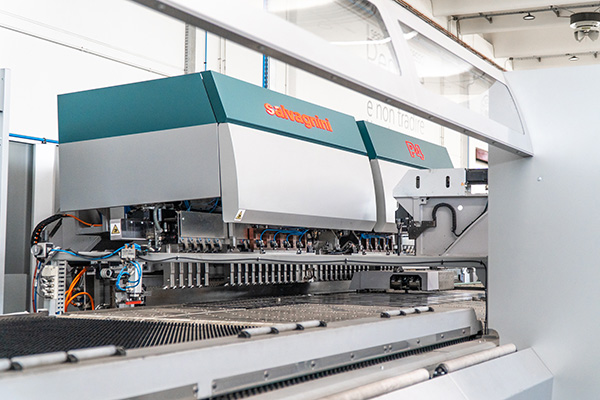

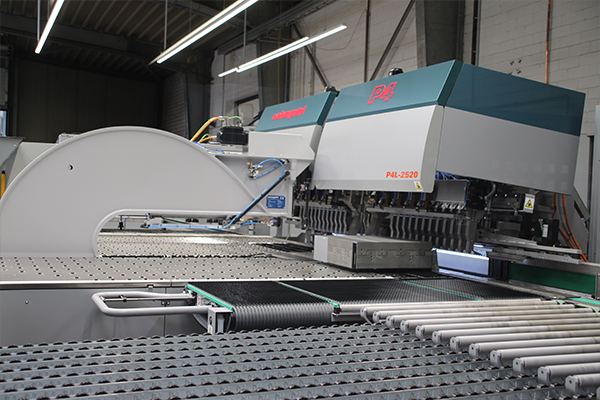

"This layout and configuration, combining the S4+P4 and B3.ATA with a mini-tower intermediate store for sheet blanks destined to our US plant, is the first of its kind in Sweden. We’re talking about a highly refined solution developed by Salvagnini’s Italian R&D team, where mechanical engineering and digital, computer-controlled production are fully integrated," says Production Manager Thomas Pettersson at Revent.

Revent is a world-leading innovator and manufacturer of rack ovens for premium bread and baked goods. The company’s latest product line, the ONE series, features a rounded baking chamber and a sliding door with an intelligent three-pane glass system—setting a new benchmark for energy efficiency, cost effectiveness and flexibility. Revent is a global company with four sales offices and two production sites in Sweden and the USA. Its ovens are used every day in bakeries in more than 100 countries.

Invest in the latest that the world’s leading machine builders can offer, ideally going all in to future-proof quality and efficiency.

"We started scouting the market early because we needed new machines and, above all, new technology, to future-proof our production. Our aging equipment and reliance on subcontractors had to be upgraded, and more capability brought in-house for better control."

We’re sitting here talking about the best thing there is, machines and manufacturing, and when, as we are today, we get to dive into the very latest in sheet metal forming, it’s hard not to be energized and inspired to witness what every manufacturer dreams of: a fully computer-controlled, automated production line, fully loaded.

"From the outset, we saw kit production as a vision of the future, but at first we weren’t sure about what Erik at Salvagnini was proposing. In my view, other suppliers couldn’t offer true one-piece kit production, they promoted smaller batches as the most efficient model instead," says Thomas Pettersson at Revent, and continues. "After numerous reference visits in Sweden, Italy and Austria, where we ran kit production trials with all the necessary machine technology, we found that Salvagnini’s specialists and technicians could provide what we needed to develop our production and create the added value required to invest in Salvagnini’s Smart Factory concept."

"My role is to engage everyone who needs to be involved to make this possible, and Erik Arden was careful to bring the entire team along, supporting training and skills development. You can invest in machines, but if you don’t equip your people with the right tools to succeed, it won’t work," says Marko Jovanovic. "The support from Salvagnini has been outstanding. Project Manager Ricky Hansson and Erik Arden have been key drivers, building bridges between our teams and Salvagnini and bringing the project to a successful close," he adds.

"It’s absolutely crucial that we mobilize the whole organization, from CEO to Production Manager to production engineers and machine operators, if we want to succeed. We’ve invested countless hours to reach our shared goals with this machine investment," says Erik Arden, Sales Manager, Salvagnini Scandinavia.

Automation and philosophy, the Salvagnini way.

"After 27 years in the sheet metal industry, many years in production and sales, and the last eight as a machine sales specialist, I’ve picked up some key drivers to keep in mind," says Erik Arden, and continues: "Flexible automation means transforming sheet metal into a wide range of products cost-effectively and without manual operator set-ups, through a progressive production flow, enabled by proprietary punching, shearing/cutting, bending and panel bending technologies in dedicated process steps."

Being competitive today isn’t only about producing individual parts quickly; the real challenge lies in the efficiency of every single process step. Flexible, autonomous and smart systems are decisive for managing production, while improving quality and reducing lead times and scrap.

Efficiency gains come from the ability to reduce or, ideally, eliminate, redundant activities and low-value work, which typically occur upstream and downstream of individual systems for preparation, feeding and interfacing.

What should you watch out for?

"There’s no point focusing on extremely high-performance technology without addressing the bottlenecks before and after production. Saving a few seconds on the cycle time of a single processing step brings little benefit if rework, intermediate stages between workstations, or a burdensome process full of redundancy, delays and inefficiencies cancels out the efficiency gained through the new system’s performance," explains Erik Arden.

As the plant visit comes to an end, we can clearly see the common thread: flexibility, and the strength of the Italian machine builder Salvagnini’s manufacturing philosophy throughout the manufacturing process, with a strong emphasis on digitalization/software and, ultimately, virtually zero set-up time.

Salvagnini is, at its core, known for large production lines, and today we offer customers increasingly smart machines with fast, automatic changeovers. This is ideal for kit production or batch size one even with high throughput and small batch runs, supported by rapid changeovers.

"Manufacturing companies often struggle with expensive changeovers, long set-up times and shrinking batch sizes, while the number of orders to manage has increased the demands for more automated layouts," says Erik Arden.

And here Erik highlights something particularly important: "Our philosophy has always been and still is to maximize automation and robotics throughout the process. With our solutions, companies can achieve fast changeovers, which are so critical today. With our unique software, we can synchronize the machines so they automatically carry out every step all the way to a finished part. One example we’ve seen today is a manufacturing system consisting of an MD storage system, S4+P4 and B3.ATA."

As mentioned, the line is fully automated and connected to Revent’s MRP system. Direct order handling is managed via Salvagnini’s OPS software, which routes jobs through a fully automated storage system, on to the S4+P4 production line and the B3.ATA, and finally to the assembly stations.

There is no set-up time in the system. The S4 keeps all the punching tools ready thanks to its unique multi-press head. The P4-2520 is fully equipped, including CLA/SIM, option CUT, P-Tool and more. It also includes the B3.ATA with its unique fully automatic tool adjustment.

Everything runs fully automatically; the operator simply needs to move the sheet, guided by monitors positioned alongside the production line. Each part is labeled by a built-in printer integrated in the S4 punching head. If a part goes astray, the operator can scan the label and the system will direct it to the correct destination: smart factory in action.

"That’s what digitalization and Industry 4.0 are about: making solutions easy to use, so you can focus on control and production process optimization. Salvagnini has been turning this into practice since 1993, when it launched OPS, its modular platform for order handling and production management," concludes Erik Arden.