Case study

Panel bender and automation create new opportunities for Alfing in Älmhult

Story and pictures courtesy of Tidningen Maskinoperatören

Manufacturers still carry latent capacity in underused production hours and avoidable changeovers. By standardizing work and connecting people, machines, and software, that capacity becomes measurable and actionable. Salvagnini’s approach combines integrated automation, adaptive technologies and advanced software to enable safe unmanned operation, stabilize quality and sustain high utilization, especially in high-mix, small-batch production with short lead times.

Investment in a state-of-the-art panel bender

We are visiting Älmhult, where Alfing has, over many years, developed a manufacturing centre comprising several factories and a complete machinery setup for efficient production. However, a factory is never truly complete, as there is always a need for new machine technology, not only to handle price pressures, but also to meet the demands of ever-shorter delivery times.

"Our industry is extremely competitive, as we experience every day and every month. Today's customers come and go depending on the quotes we present, which means we are in a constant pursuit of productivity improvements by embracing new machinery and automation. If we can save minutes or hours in our processes, it translates into increased competitiveness against low-wage countries," says Sales Manager Arne Karlsson.

"For us, the next step is to optimize our machine fleet with the best machines. We already have a high degree of automation in our factories, but it can become even better and smarter. We need intelligent machine suppliers who can provide the very latest engineering designs, combined with digital software solutions that reduce programming and optimize the various bending parameters," says designer and machine programmer Philip Petersson. "Since May last year, we have entered over 800 programs into our system, and Salvagnini considers this something of a record. We are creating the conditions for producing a wide range of items in both small and larger batches or volumes," he adds.

"This is where STREAM comes into play," says Erik Arden, sales representative at Salvagnini Scandinavia, explaining all the benefits. "It bridges production technology and operators, enabling the processing, communication, and integration of information. It ensures maximum simplicity, efficiency, and purposefulness. All of this serves to control the process as a whole, to rapidly learn from experience and the surrounding environment, to interpret complex situations and give them meaning, and to solve problems. STREAM is the integrated software ecosystem for managing all activities, both in the office and on the shop floor. It serves as the single access point for all technologies, from cutting to bending, fulfilling every need for planning, programming, production, management, control, and optimization throughout the entire production process. STREAM includes five CAM modules, each connected to a specific technology, as well as the PARTS library and the VALUES cost estimation software."

"A deliberate, straight-forward, and natural technology choice, with the market leader Salvagnini providing us full support and service, from procurement and factory visits to testing selected parts and the FAT," says Rickard Petersson, from the purchasing department, who has worked at Alfing in Älmhult for over 20 years.

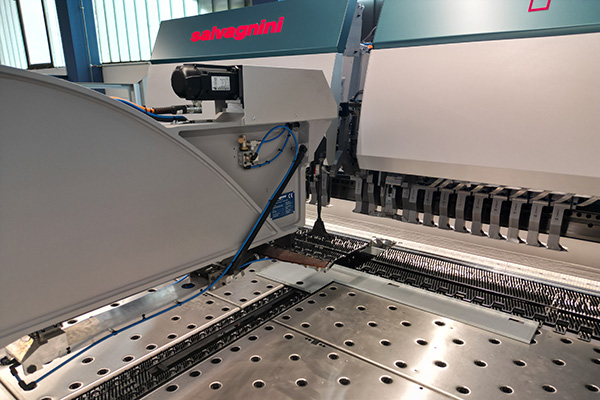

In 2024, Alfing Produktion invested in the very latest technology by acquiring a P2-2120 panel bender from Salvagnini. This state-of-the-art machine allows for increased efficiency and versatility in production processes.

"The machine is impressively versatile in sheet metal forming. With the capacity to handle sheet thicknesses from 0.4 mm to 3 mm, it provides the flexibility required for a variety of production needs. Its universal bending blade and zero setup time significantly increase productivity, meaning we’re now ready to take our production processes to the next level," says Rickard Gustavsson, who works in purchasing and production planning at Alfing in Älmhult.

"The smart technology behind the machine’s adaptive process ensures high quality and minimizes waste, enhancing workflow, safety, and final outcomes. In addition, the P2 is eco-friendly, with a low energy consumption of just 4 kW, supporting both sustainable and responsible production," adds Arden.

A new concept: robotics as a means to meet market challenges

Introduced in 2022, Salvagnini P-Robot pairs a panel bender with a robot to run kits, batches and single parts autonomously, boosting bending utilization with minimal operator workload. The gripping device, with dual-sided suction cups, handles finished parts and feeds the next blank in-cycle, reducing loading/unloading time and keeping the system productive. Programming stays lean: bending programs created in STREAMBEND can be used on P-Robot and standard panel benders, while MOVE automatically generates robot trajectories through an on-board smart teaching workflow, eliminating the need for offline robot programming. With the RVS Robot Vision System option, P-Robot uses artificial vision and AI to recognize parts and manage intermediate handling without reference points, enabling reliable unattended and collaborative production in high-mix environments.

"I want to highlight the operators and team leaders. After completing training in Värnamo, this group has carried out an impressive job over the first 8–9 months by programming and producing over 800 new panel bender jobs, on parts with large volumes, which is an extremely impressive figure. I really admire the way the team leaders and operators at Alfing work together to question every detail of what is currently produced using the traditional press brake and ask themselves whether it can be run more efficiently on the P2," says Arden. "Personnel and training are a very important part of machine investments, and we place great emphasis on this from the start with a five-day basic training course in collaboration with our training team. During the following period, operators have direct contact with our trainers, who support them throughout the programming process. Our philosophy is never to hesitate to call us if you get stuck: we are here for you. The best feeling for us is when our facilities are running at full capacity, and programming does not become a bottleneck. Since the P2-2120 is fully equipped with features such as CLA/SIM, P-Tools, and option CUT, a very large proportion of Alfing's production can be manufactured on the panel bender, all without any setup times."