Case study

Managing complexity with automation

With over five decades of experience, VETA serves hundreds of customers across Europe with a wide range of sheet metal parts. To meet the challenge of small batches, shifting designs, and labor shortages, the Greek subcontractor chose Salvagnini panel benders to drive automation in bending, reducing setup times, improving repeatability, and scaling production for global markets.

Managing complexity with automation

Highlights

- VETA

Founded in 1967, VETA is one of Southern Europe’s largest subcontract manufacturers. With 240 employees and three facilities in Greece, it serves over 500 customers annually across sectors including retail, energy, IT, architecture, and manufacturing. - The challenge

VETA’s high-mix production and small batch sizes demanded greater flexibility, consistent quality, and reduced setup times. At the same time, sourcing skilled operators was becoming increasingly difficult. - The solution

VETA adopted an automation-first strategy:

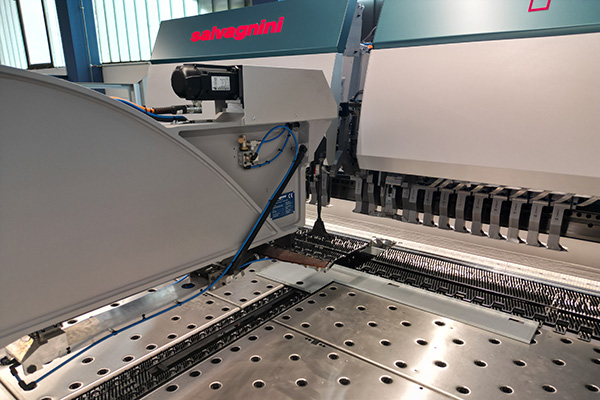

• P4-2116 panel bender

• P1 electric panel bender

Both equipped with CLA auxiliary blades for complex tabs and short-side bends. These are integrated with press brakes, including two Salvagnini B3s, to route bending operations efficiently. - The results

• Setup times reduced to near zero with ABA blankholder

• Simplified training and staffing, reducing operator dependency

• Repeatable, high-quality bending supporting robotic welding and downstream processes