Case study

Daken: taking on sheet metal challenges

Daken S.p.A. is the result of a business project that began in 1989. Founded in 2007, Daken specializes in the production of plastic accessories for commercial and industrial vehicles. Only in 2020 did the company make the decision to open new markets, by including a line of sheet metal accessories in their range. We met the owners of Daken and visited the production site, in the Jesce industrial area in the province of Matera, to see what strategies led them to choose Salvagnini as a partner for penetrating this new market segment.

Taking on sheet metal challenges

Highlights

- Daken

Daken S.p.A. is a consolidated name in the production of polypropylene plastic accessories for the automotive and fire-fighting sectors. - The context

With injection molding, Daken were bound to the molds and cannot produce off-standard. In addition, in some countries, such as Scandinavia, the USA, Canada and Australia, steel continues to be preferred, both for its strength and for a matter of philosophy. - The project

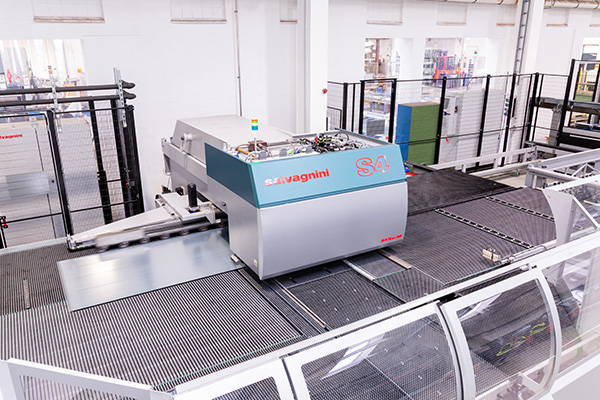

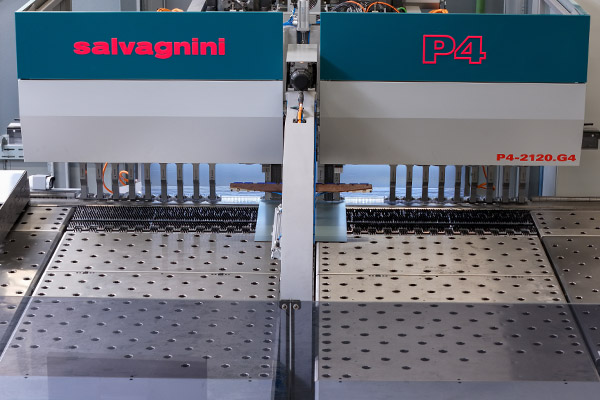

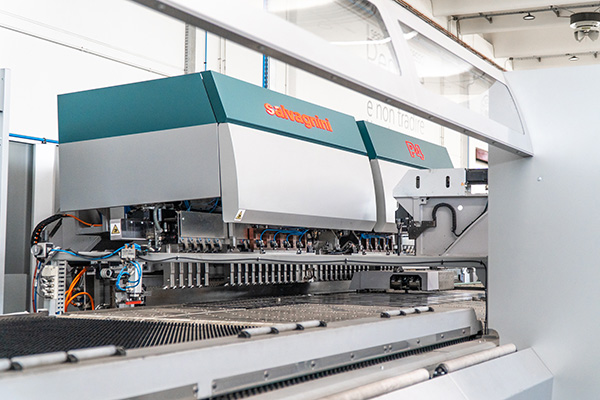

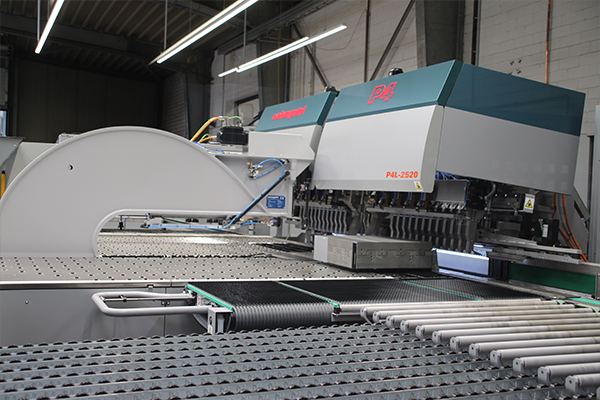

Daken’s sheet metal needs required a high level of customization. This approach led the company to look for a flexible technology which could help offering tailored solutions, at the same time optimizing the process. After an in-depth analysis, the choice fell on a Salvagnini flexible manufacturing system. - The outcome

"Today our strategy is just in time, and this allows us to efficiently manage the mix of standard products and custom products without stocking huge quantities of semi-finished parts in the warehouse: a huge economic and logistic benefit," explains Luca Corrado, Daken Plant Manager.