Case study

Altex: L5 investment means success is in the air

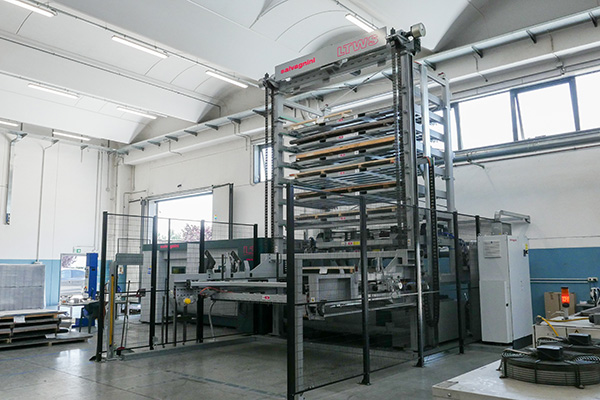

Altex Engineering, a leading precision subcontractor based in Calne, has invested in a new Salvagnini L5 fiber laser cutter to increase capacity and meet growing demand. Established over 30 years ago by current owner John Jackett, the company has grown into a 30-employee business with UK-wide customers in sectors such as medical, telecommunications, defence and office furniture.

L5 investment means success is in the air

Highlights

- Altex Engineering

Established over 30 years ago by current owner John Jackett, Altex Engineering has grown into a 30-employee business with UK-wide customers in sectors such as medical, telecommunications, defence and office furniture. The company, which undertakes fabrication, machining and finishing operations, extended its Wiltshire premises in 2014 and today commands space of circa 20,000m2. - Step by step investment

“Due to rising orders, we recently ran out of capacity on our existing Salvagnini L1Xe laser cutter,” explains Mr. Jackett. “We therefore took the decision to invest in another machine. I looked at several machines but the L5 was best.” - High power density

In combination with the new 6kW high power density source, the L5 is notably faster than previous-generation models. For instance, in tests against the company’s L3 with a conventional 6kW source, cutting times were 30-40% quicker on materials up to 3mm thick, and 10% quicker on 4mm thick material. From 6-10mm, the performance was the same.