Case study

Forster: fully automatic, highly dynamic laser cutting

Story courtesy of Ing. N. Novotny/Blechtechnik

In order for the Lower Austrian plant in St. Peter in der Au to be able to react in an even more flexible manner and further expand its machining spectrum, Forster Metallbau GmbH has invested in a new Salvagnini laser cutting system. A store-tower including automatic loading and unloading as well as an automatic sorting device for cut parts make the laser a fully automated.

Fully automatic, highly dynamic laser cutting

Highlights

- Forster

Forster stands for long-standing tradition combined with state-of-the-art technology. What started in 1956 in a former hammer mill with the production of embossed signs developed into one of the leading industrial companies in Mostviertel, which offers sophisticated solutions in the areas of traffic technology, noise protection, shelving systems, object labeling, advertising technology and industrial printing. - The context

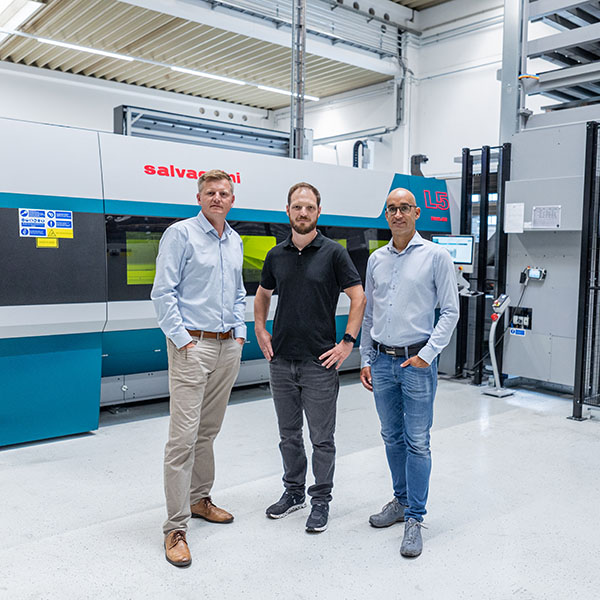

In February 2020 the Forster Group was one of the first companies in Austria to be certified according to ONR 192500. “Developing and manufacturing sustainable products is particularly important to us. We pay particular attention to using materials and energy as efficiently as possible. It must also be absolutely possible to recycle them: our products are made mostly of steel and aluminum, and both materials can be 100% recycled”, says Andreas Grader, CEO of Forster Metallbau. In addition to decades of experience in metal processing, the Forster Group is distinguished by its state-of-the-art manufacturing technologies as well as its readiness to innovate. “This results in excellent product quality which is proven by numerous quality marks”, illustrates Grader. - The project

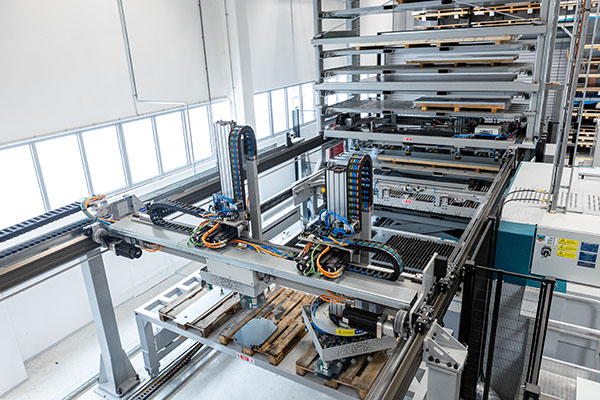

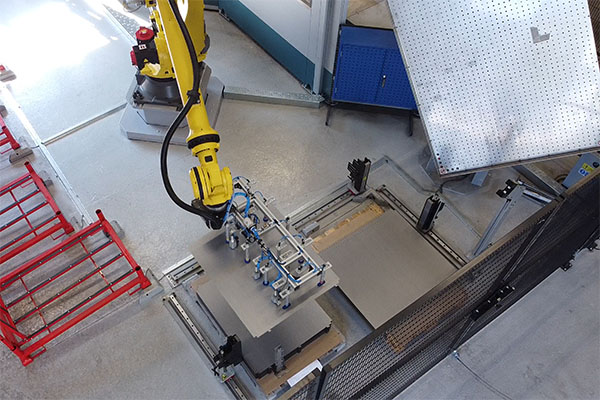

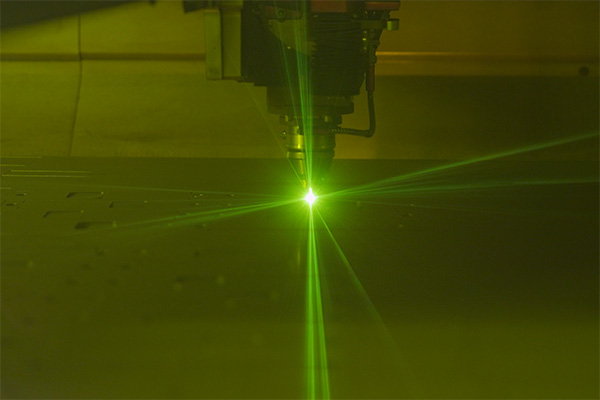

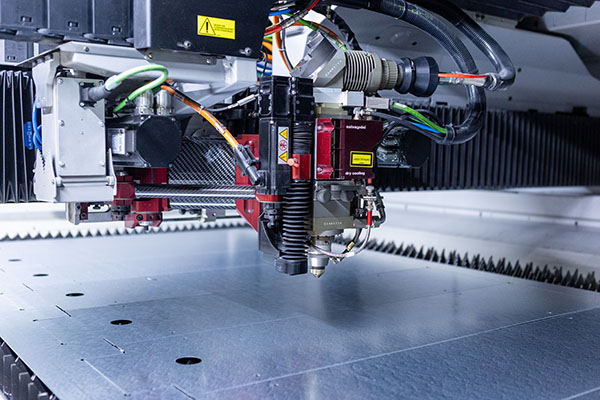

The fully automated laser cutting system from Salvagnini which this year replaced an aging automatic punching-shearing system from the 90s is proof of the company's use of state-of-the-art manufacturing technologies. “As the components machined on the previous machine with the required punching operations, such as large perforation surfaces or 3D- forming operations, could be moved to an existing punch-laser combi machine, we decided to install a pure yet more powerful and fully automated laser for our production,” explains Thomas Prantner, Plant Manager at Forster Metallbau. The L5 laser cutting system is fed by a Salvagnini LTWS store-tower, which is responsible for automatic, unmanned loading and unloading as well as storage of material. “The store-tower is used for storage of the pending production orders and is filled in advance by the operators” explains Prantner. In order to be able to accommodate sufficient semi-finished products, the storage area was redesigned when the new laser was installed: “It now offers space for more than 200 sheet metal packs and guarantees short distances for the forklift for storage in the store-tower.” - The outcome

After about six months of use, Forster Metallbau is still enthusiastic about the new system: “Thanks to Salvagnini's new laser we were able to considerably increase our production flexibility. In addition to expanding our machining options regarding thicknesses and complex component contours, the Salvagnini L5 has satisfied us with its excellent cutting times and user friendly operation”, according to Prantner, who also mentions the low energy and operating costs of the fiber laser technology.

Check out the case study

Hear what Andreas Grader, CEO of Forster Metallbau, says about this project.