Case study

A thousand different sheet metal parts

Story courtesy of E. Weustink/PlaatBewerkingsNieuws

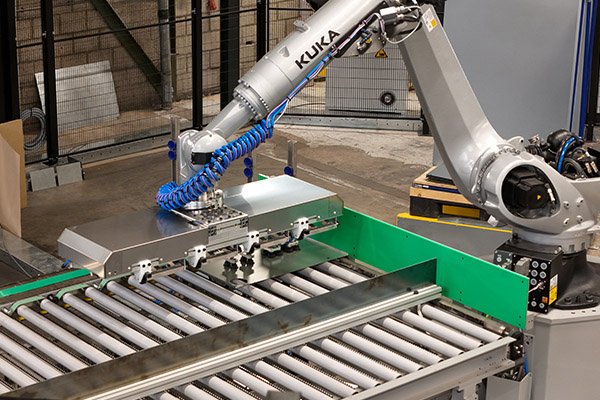

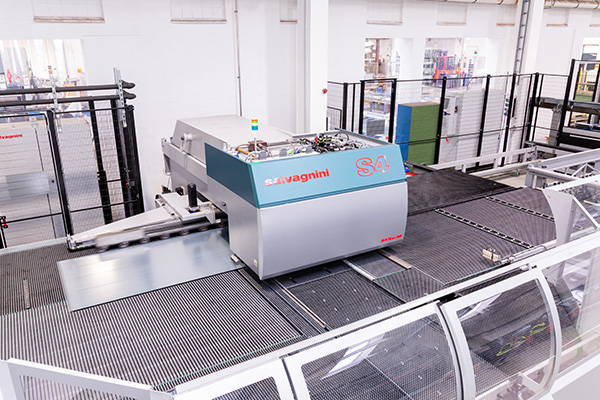

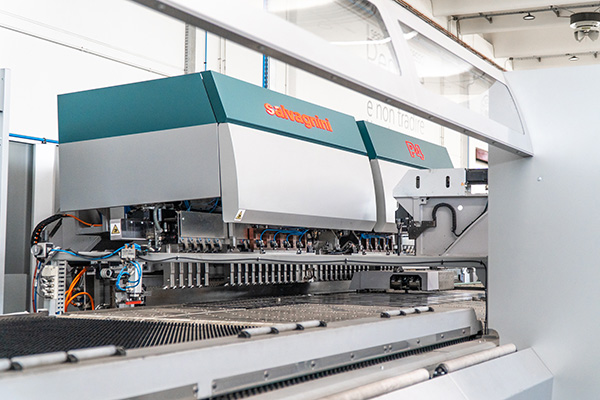

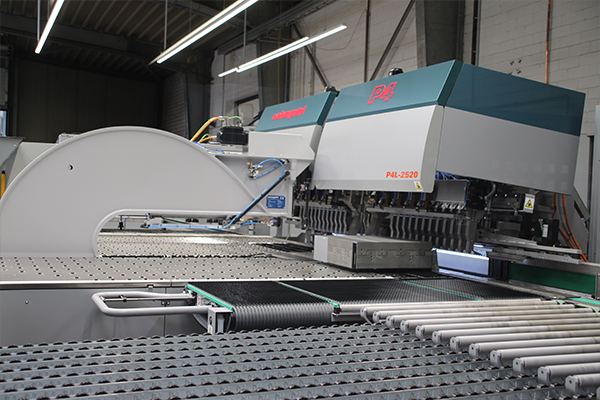

Shortening lead times and reducing intermediate stock levels: these were the main reasons why Gamko decided to invest in a new Salvagnini FMS production line. The line includes a sheet metal tray store, a punching-shearing center, a sorting device, a panel bender, and a robot for unloading the finished parts. An AGV then removes the products from four pallet positions and transports them to a buffer zone. With this line, Gamko is taking a major step toward autonomous production.

A thousand different sheet metal parts

Highlights

- Gamko

Gamko, a Netherlands-based manufacturer of professional bar coolers, produces entirely in-house at Etten-Leur. Materials range 0.5–2 mm, usually film-protected, requiring punching, shearing and bending. To shorten lead times and reduce intermediate stock, Gamko pursued higher automation. - Challenges

Standalone machines created intermediate stock and floor handling, inflating WIP and risking delivery lead times. Labor scarcity pushed for automated, lights-out capability. The new line also had to fit the existing plant with minimal structural changes. High product mix strained flow and setup efficiency. - The solution

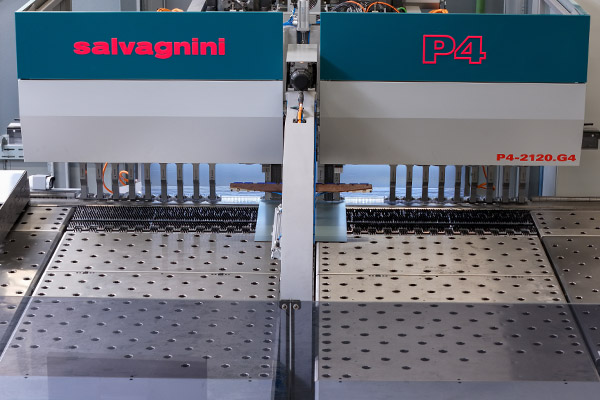

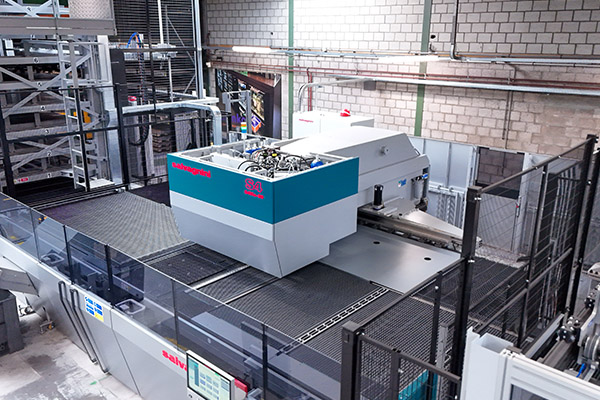

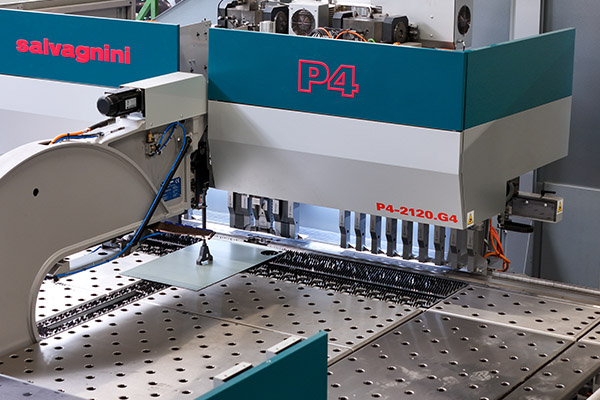

Gamko implemented a Salvagnini S4+P4 FMS that unifies storage, punching, separating and bending in a single automated flow. An automated sheet metal tray store feeds an S4 punching-shearing center, ensuring steady supply. Blanks then travel through the MCU sorting device and the RIP turnover unit to a P4-2120 panel bender for fully automatic bending. A robot sorts finished parts onto four pallets, while an AMR transfers them to the unloading bays, sustaining mixed-model throughput and enabling stable, continuous production. - The results

Startup was smooth; hundreds of products in week one. The line bends ~90% of parts, synchronizes flow, and supports mixed-model production. Robot and AMR enable an unmanned night shift; low tool wear reduces maintenance. “A tremendous number of products are coming off the line. We've significantly increased our production capacity,” says Patrick Bliek, Manufacturing Engineer at Gamko.