Case study

ICET INDUSTRIE: industrializing flexibility

Story courtesy of S. Franza/Lamiera

One of ICET INDUSTRIE S.p.A.'s main businesses is the production of totally customized electric switchboards. And it is precisely customization that allows the company to differentiate in a market governed by modularity. To combine high flexibility with high productivity, ICET INDUSTRIE S.p.A. chose Salvagnini's high-performing FMS line.

Industrializing flexibility

Highlights

- ICET INDUSTRIE

ICET INDUSTRIE S.p.A. is an Italian company. It has 270 direct employees and a turnover of 40 million €. - The industry

The switchboard industry is highly competitive, and it works mainly to order. Generally switchboards are built in standard modules, with little possibility for customization. - The project

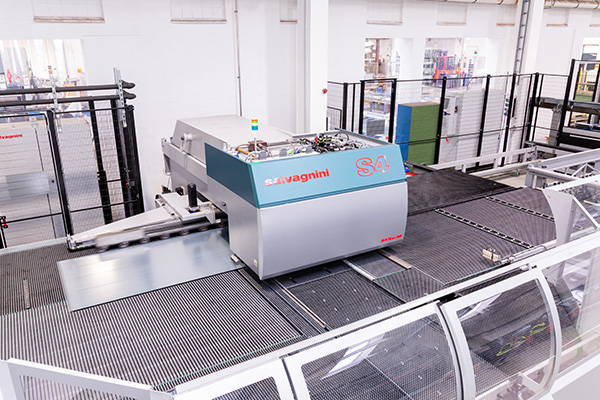

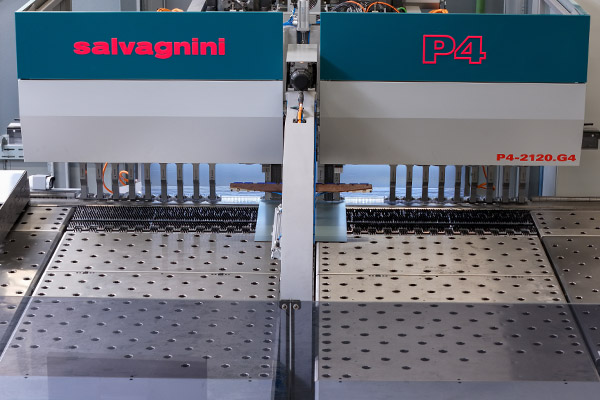

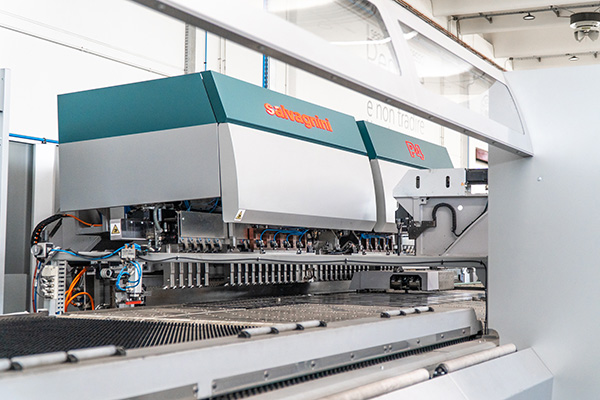

In 2021, ICET INDUSTRIE S.p.A. acquired a Salvagnini S4+P4 line consisting of a MD automatic single sheet store-tower, S4 punching machine, MCU sorting device and P4 panel bender. The FMS had to be integrated with a static tray store already installed in the facility. - The outcome

The introduction of the Salvagnini line reduced the cycle time of some products by over 35%.