Case study

METAGRO: a new panel bender opens up new opportunities

Story courtesy of S. Winter/Blechtechnik

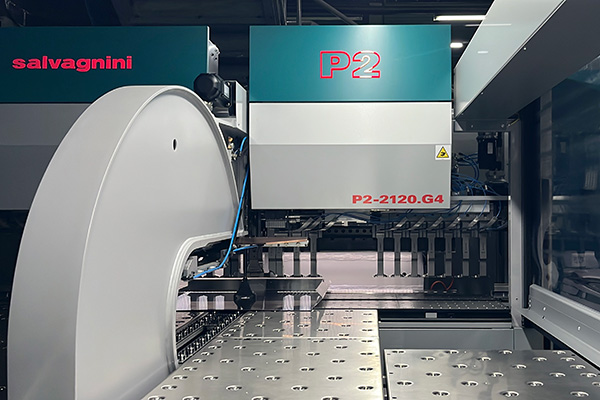

Talks between METAGRO and Salvagnini had been held periodically. However, it took about fifteen years before the panel bender made in Ennsdorf was installed in Hainfeld. Now– only a few months after putting it into service – this Austrian company that specializes in the manufacture of high-quality stainless steel products cannot imagine its production without the P2. After all, choosing this bending solution that does not require any tool setup resulted not only in higher process quality but also in opening up additional business opportunities.

A new panel bender opens up new opportunities

Highlights

- METAGRO

METAGRO was founded by Eng. Peter H. Reuschel. While working as a coffee machine salesman, he discovered an interesting market niche – tailor-made stainless steel furniture for the food industry – which he intended to fill with his own product offer. The official opening for his company was dated 1972, and one year later, with 14 employees, he started to produce mainly batch-one items and medium-sized batches. - Project requirements

Overall, METAGRO had many requirements for its new bending solution: it had to be compact, as the “only” space available is where its predecessor - a hydraulic press brake - was located. It had to adapt to the current product spectrum of the company, keeping at the same time lots of margin for future projects. It also had to comply with the most modern state-of-the-art technology. - The output

“With this machine we are able to cover a larger variety of stainless steel products. A considerable amount of idle time for set up and programming has been drastically reduced. Also the bending of various radii as well as larger bends and adapted contours is possible with higher quality thanks to the new panel bender. In the past we often had to purchase individual tools. With Salvagnini’s intelligent Material Attitude Correction technology, the same high-quality bends are guaranteed for a wide range of sheet clamping operations. Another aspect from which we benefit considerably: extremely high repeatability within a range of a tenth of a millimeter. Small gap dimensions are constantly ensured, which is very helpful for the downstream processes – such as semi-automated welding,” says the Production Manager Matthias Uhrfahrer, explaining the multitude of improvements that he would no longer want to do without.

Check out the case study

Hear what METAGRO executive team says about the Salvagnini P2 panel bender.