Case study

Panhuber: all-in-one punching and bending

Story and pictures courtesy of N. Novotny/Blechtechnik

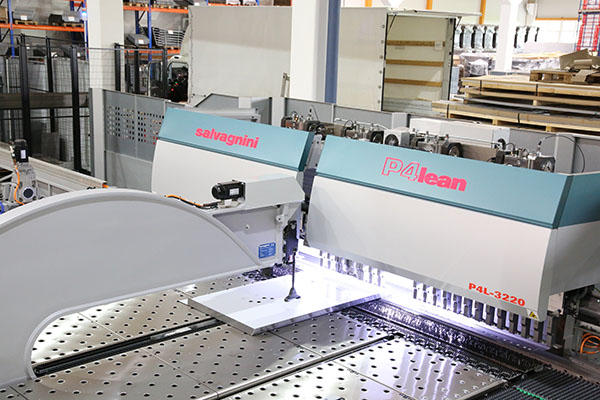

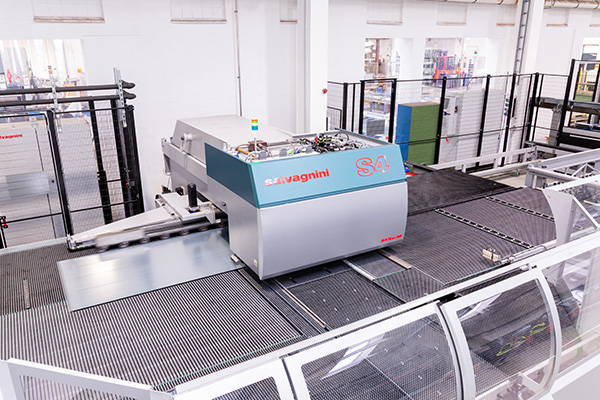

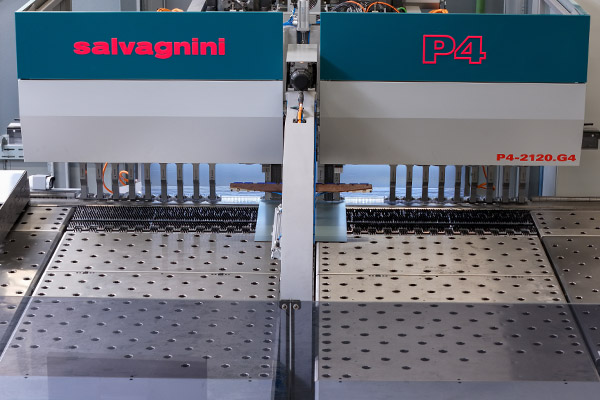

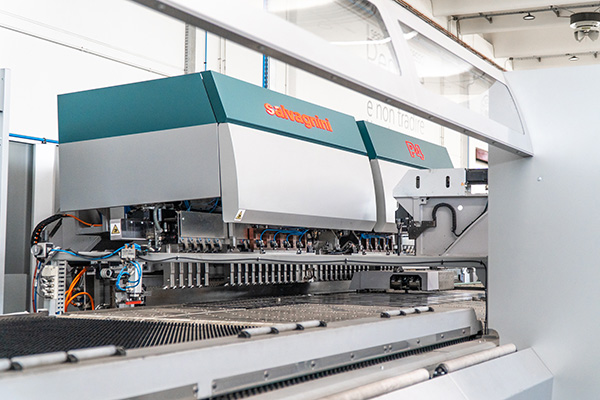

As a highly specialized sheet metal processor, Panhuber GmbH looks to the future regularly by investing in its machinery. This family company from Austria has entrusted its laser cutting, punching and bending to Salvagnini machines for 20 years. In order to ensure that sufficient manufacturing capacity is available for the continuously growing order volumes, a third brand-new S4+P4 line was put into operation at the beginning of the year.

All-in-one punching and bending

Highlights

- Panhuber

In 1983, Wolfgang Panhuber purchased a metalworking shop in Taufkirchen an der Trattnach (Upper Austria) and established Panhuber GmbH with his wife Josefa. Today Panhuber GmbH has approx. 6,500 m2 of production space available for processing more than 2,000 tons of sheet metal every year, currently with approx. 20 employees. - The context

The first Salvagnini machine was put into operation at Panhuber exactly 20 years ago. It was one of the first laser cutting system installed in Austria, an L1. Since then, with Salvagnini, the company gained an extremely important partner. - The first S4+P4 line

“The investment we made in the mid 2000s in the first S4+P4 line was another milestone for us,” recalls Wolfgang Panhuber. At that time, the company from Taufkirchen was searching for a system they could use to produce boiler coverings made of delicate, pre-painted sheet metal without scratching it, in an automated production flow from punching to bending, for one of their customers. With the Salvagnini S4+P4, they were able to solve the problem thanks to line production without any intermediate handling so as to prevent any damage to the parts. - Increase capacity, again

To meet the necessary production capacity, Panhuber purchased and installed a third S4+P4 line, which has been in use since the beginning of 2021.

Check out the case study

Hear what Panhuber executive team says about Salvagnini machinery.