Case study

Steurer Systems: ski depot , drying, and cloakroom systems from the Alpine region to the whole world!

Story and pictures courtesy of N. Novotny/Blechtechnik

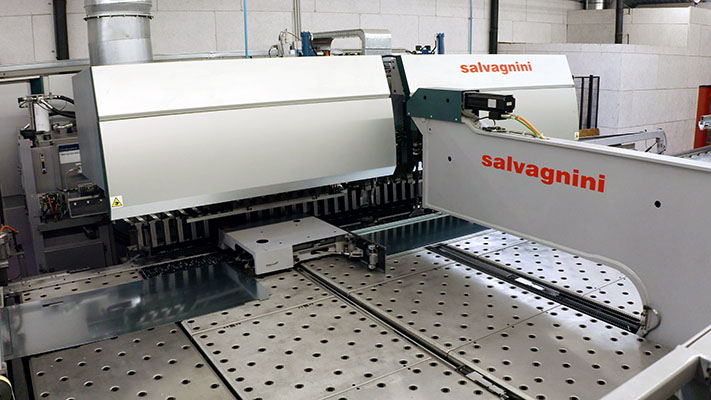

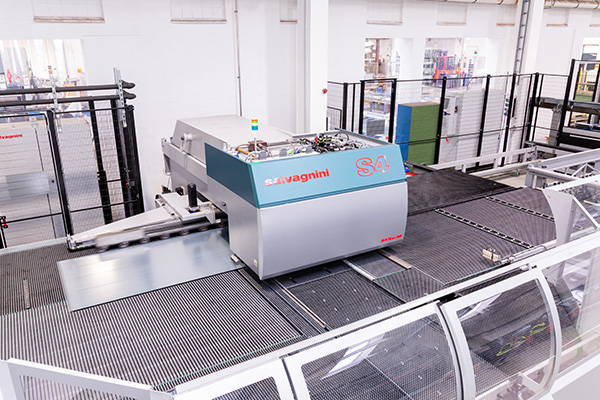

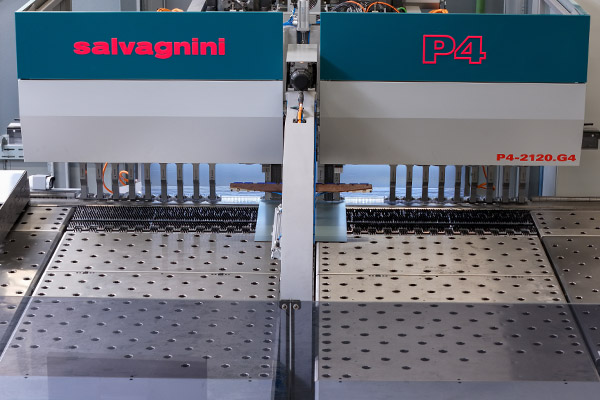

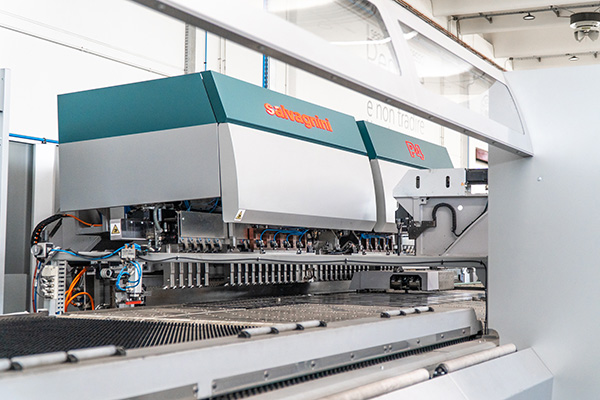

To switch from a traditional production layout, including a punching machine and downstream manual and robotized bending, to a fully integrated production system in order to boost flexibility and maximize capacity with the same staff: this is the ambitious project that Steurer Systems, an Austrian company that designs, manufactures, and installs ski depot systems, drying and cloakroom systems, started at the end of 2011 with the installation of a Salvagnini S4+P4 line.

Ski depot, drying, and cloakroom systems from the Alpine region to the whole world!

Highlights

- Steurer Systems

Cutting-edge ski depot systems, drying, and cloakroom systems are not just classic lockers: they are now integrated drying and hygiene solutions, featuring advanced technology and electronics. Steurer Systems knows this well as it has been setting technology, design, and quality standards in ski cabinet manufacturing for decades. And this is exactly why its products can be found almost worldwide, from Scandinavia to Japan, from Russia to the USA. - The context

“Back in 2011 we chose a Salvagnini precisely because we wanted to grow, take the next step, and enter the future. We dismissed a jobshop organized by separate workstations – a punching machine which was already automated at that time, combined with downstream manual and robotized bending – and we moved onto a fully integrated production system,” says Andreas Seidl, Steurer Systems Managing Director. - The benefits

“With the same staff we achieved approximately 70% more capacity, but we also boosted our flexibility. Today we process batch sizes from 1 to unlimited, we have overcome technological constraints that were impossible to cross with traditional machinery, and we run low-staffed shifts – which is a major benefit,” says Seidl. “Depending on the size of the parts, we produce between 600 and 1000 parts in 24 hours, and we run the line 24/7: during the week we mix manned/unmanned production, while during the weekend we mix manned/on-call production. In peak periods, the system runs at full capacity both during the week and at the weekend.”

Check out the case study

Hear what Andreas Seidl, Managing Director at Steurer Systems, says about this project.