Case study

Teklan: a subcontractor with cutting-edge equipment

Story and pictures courtesy of I. González/Revista TOPE

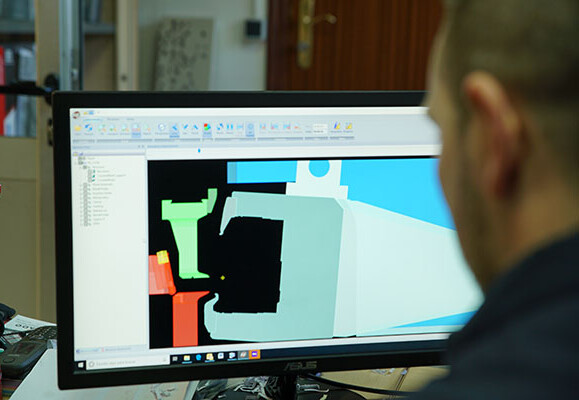

As a sheet metal processing company, Teklan, S.L. (Hernani, Gipuzkoa) boasts more than 20 years' experience in cutting, machining, punching, bending and forming sheet metal. Brands like Salvagnini, one of its main suppliers, guarantee delivery time and optimum end product quality for all parts supplied to the customer.

A subcontractor with cutting-edge equipment

Highlights

- Teklan

Established at the beginning of 1997, Teklan is a Spanish, Gipuzkoa-based subcontractor. The company operates out of a plant measuring some 6,000 square meters and with the latest hi-tech excellence in machinery, allowing the processing of sheet metal in ways that are beyond the reach of most subcontractors. - The machinery

“We are subcontractors, so when it comes to investments it is not the same as if we had our own product. We have no choice but to move forwards. Technology keeps advancing and we have to too: we cannot get stuck with a fifteen year-old machine. Nowadays, with the computer, the drawings are really beautiful, and then they have to be processed: we need machines that can do that. Salvagnini machinery obviously can: we are confident that it will help us to stay strong in the market,” says Iñaki San Sebastian, Teklan Director.

Check out the case study

Hear what TEKLAN executive team says about Salvagnini.