Simply the line

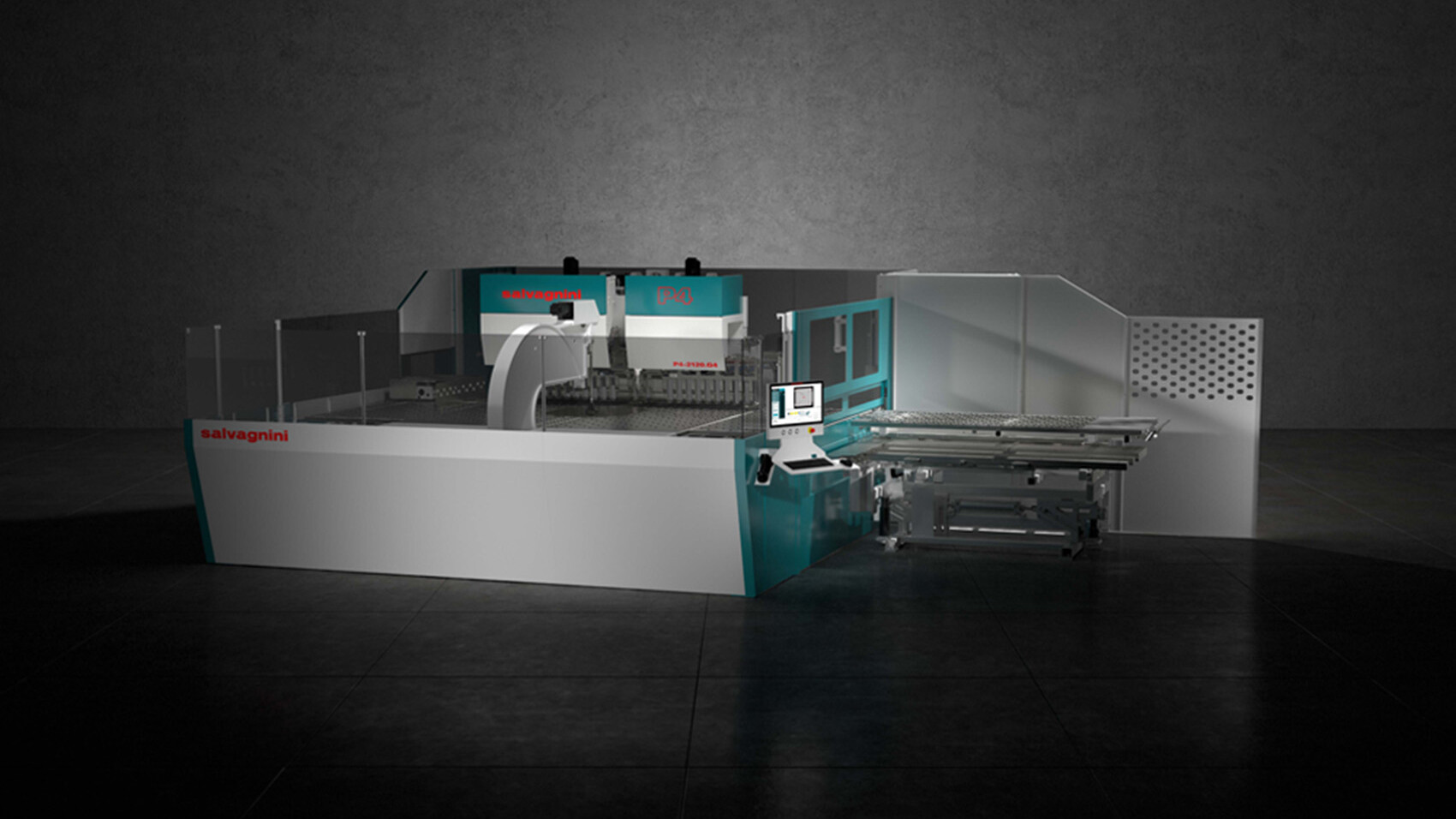

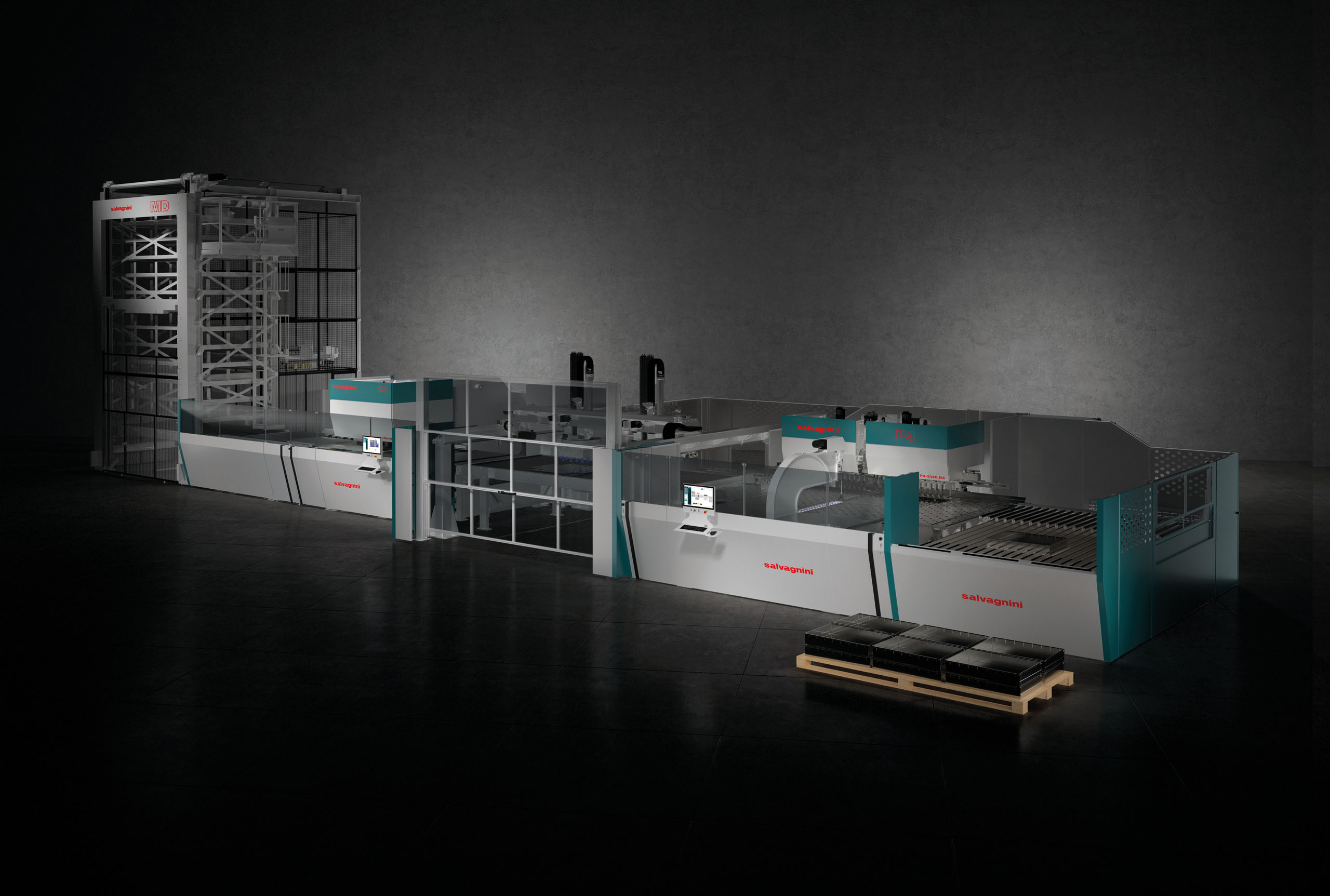

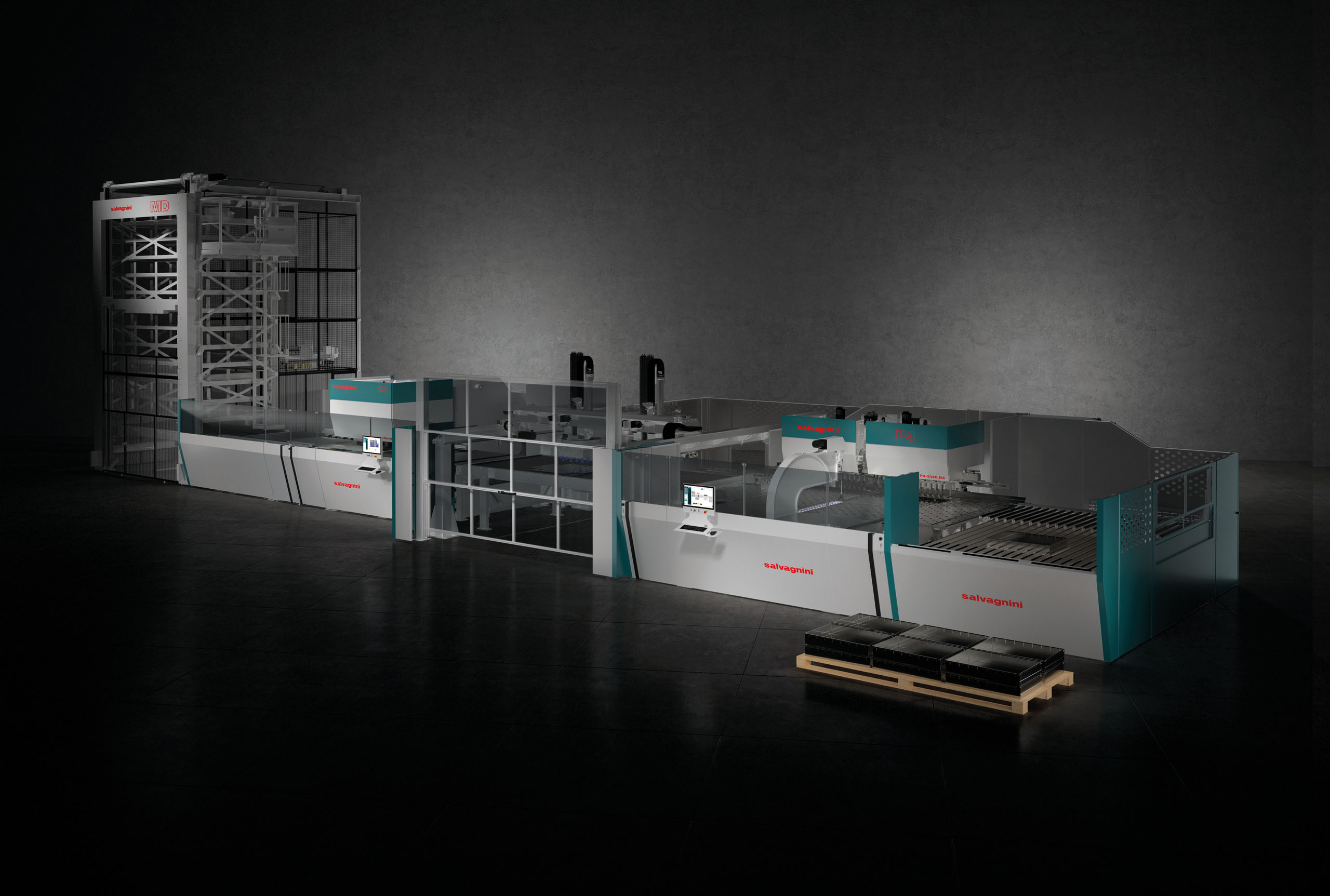

FMS Line

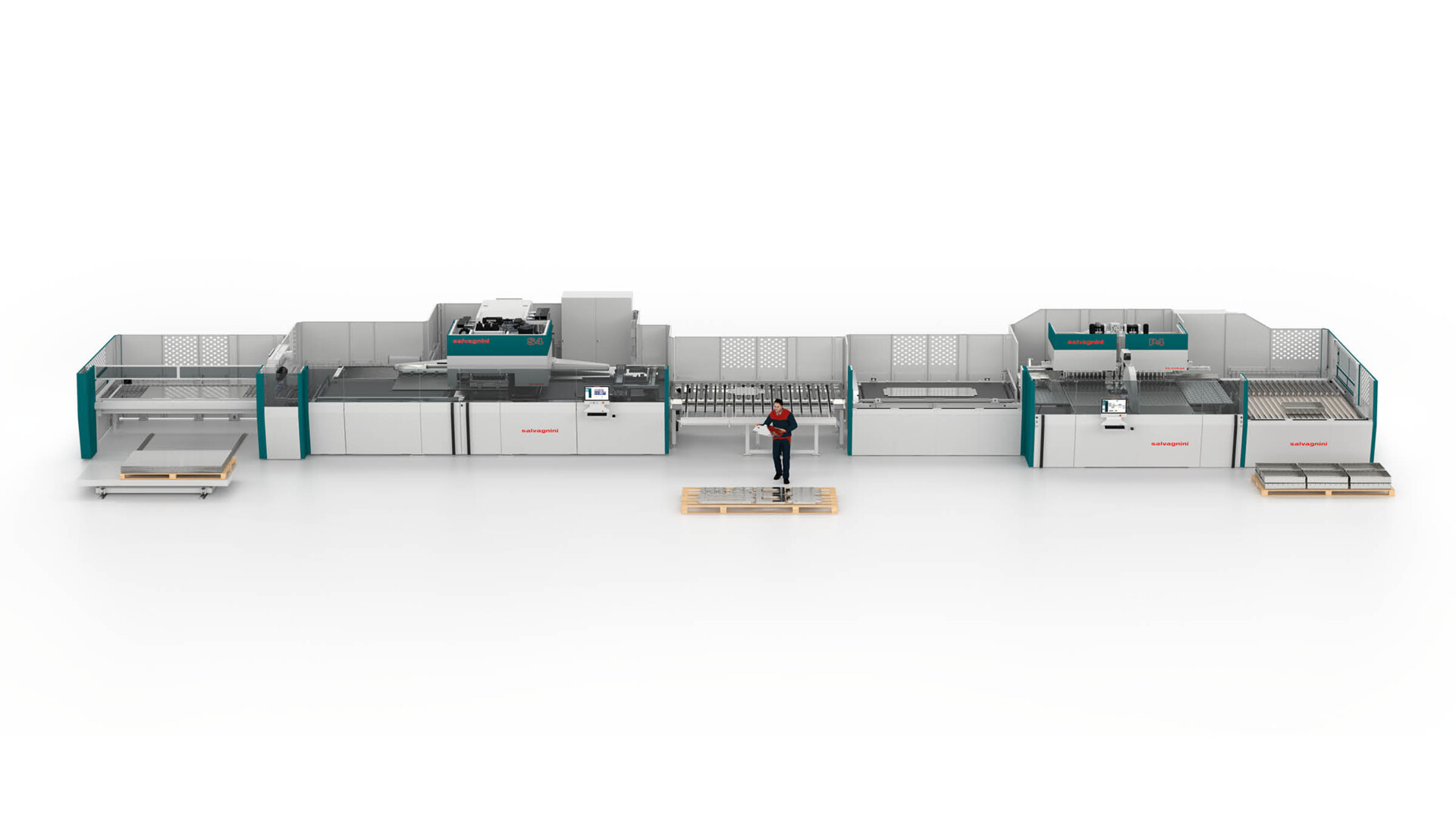

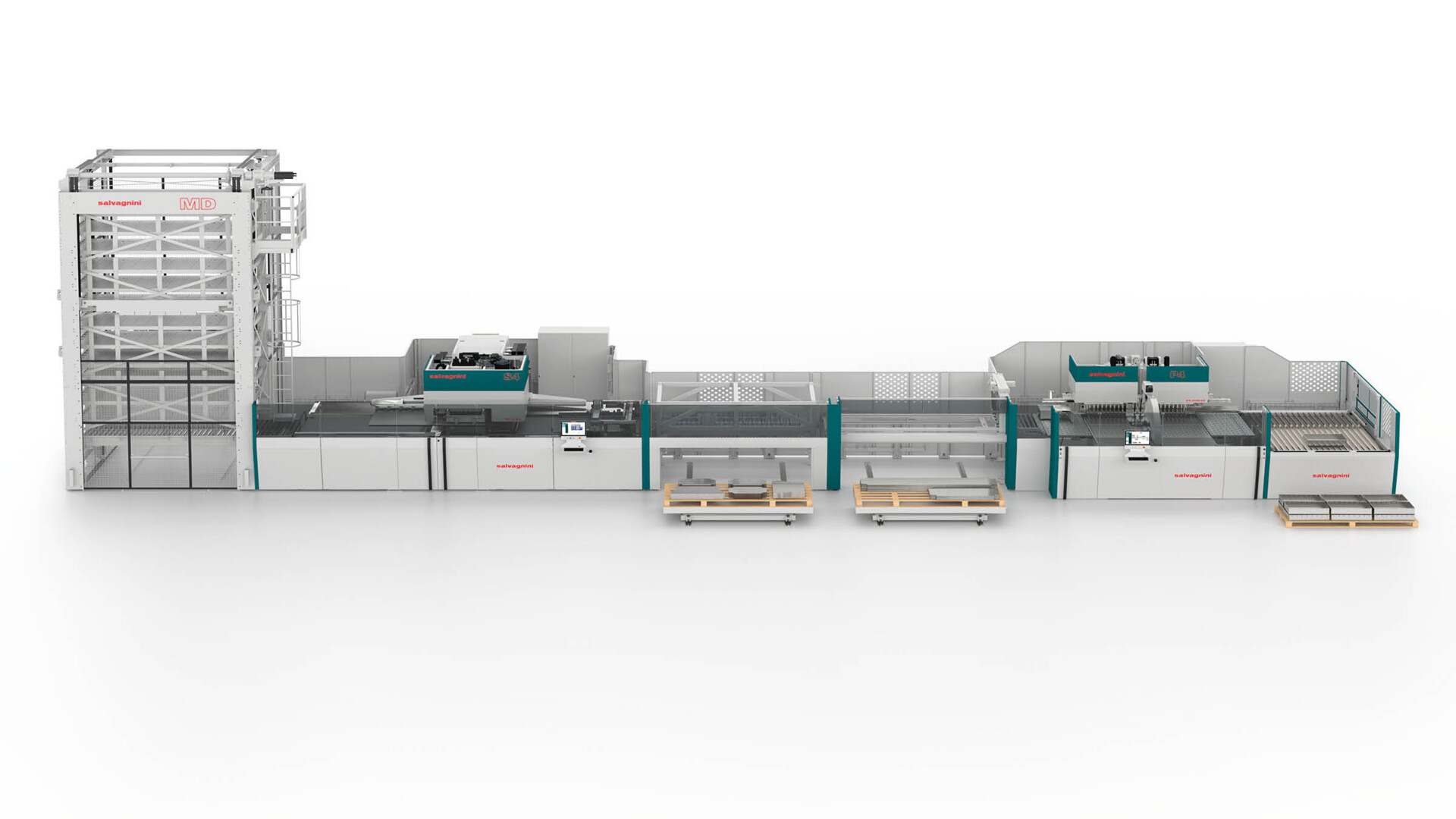

Automatically punches, cuts and bends sheet metal without intermediate handling. The ideal solution for any production strategy, be it kit, single-batch or series production.

The S4+P4 line ensures continuous production of kits and batch ones, minimizing cycle times, semifinished parts and intermediate handling, eliminating tool changes.

100% flexible automation

Fast-flow jobs, 100% guaranteed

The S4+P4 line punches, shears and bends sheet metal totally automatically, without any intermediate handling. Among other benefits, the line allows to produce on demand and just in time, to increase capacity and velocity, to reduce lead time, to process different materials without retooling, to optimize manpower activities.

The parts, from raw material to bent panel, cross through all the work stations continuously and in a short time, minimizing through-times and optimizing performance. The line intelligence, that knows the processing and through-times of parts and machinery, autonomously manages the station availability, optimizing the result according to the production strategy.

Flexible Factory Line Overview

Uplevel your production process with the S4+P4, the ultimate sheet metal automation solution that punches, cuts, and bends with precision and speed, streamlining your workflow for any production strategy - whether it's kits, single batches, or series production. Salvagnini's S4+P4 line is more than a unified product; it's a promise of unparalleled efficiency. By combining the strengths of two powerful machines, this holistic FMS solution handles the punching, seeing, and bending without any intermediate handling. Since 1979, Salvagnini has been at the forefront of FMS innovation, redefining sheet metal fabrication. Embrace the future of manufacturing and elevate your productivity with the flexibly factory line today!

Product overview

The integrated adaptive technologies make the S4 intelligent and able to automatically adapt to variations, eliminating waste and corrections, while guaranteeing high machining quality:

- the centering control system measures the incoming sheet and adapts the program to the actual dimensions measured, if necessary;

- the manipulator changes its dynamics according to the size and weight of the sheet, opening the pincers according to the percentage of sheet machined;

- an automatic system checks the thermal expansion of the manipulator’s axes and compensates any variations, guaranteeing extreme positioning precision;

- the shear automatically records the clearance and, depending on the thickness and the material, modulates the required force in-cycle.

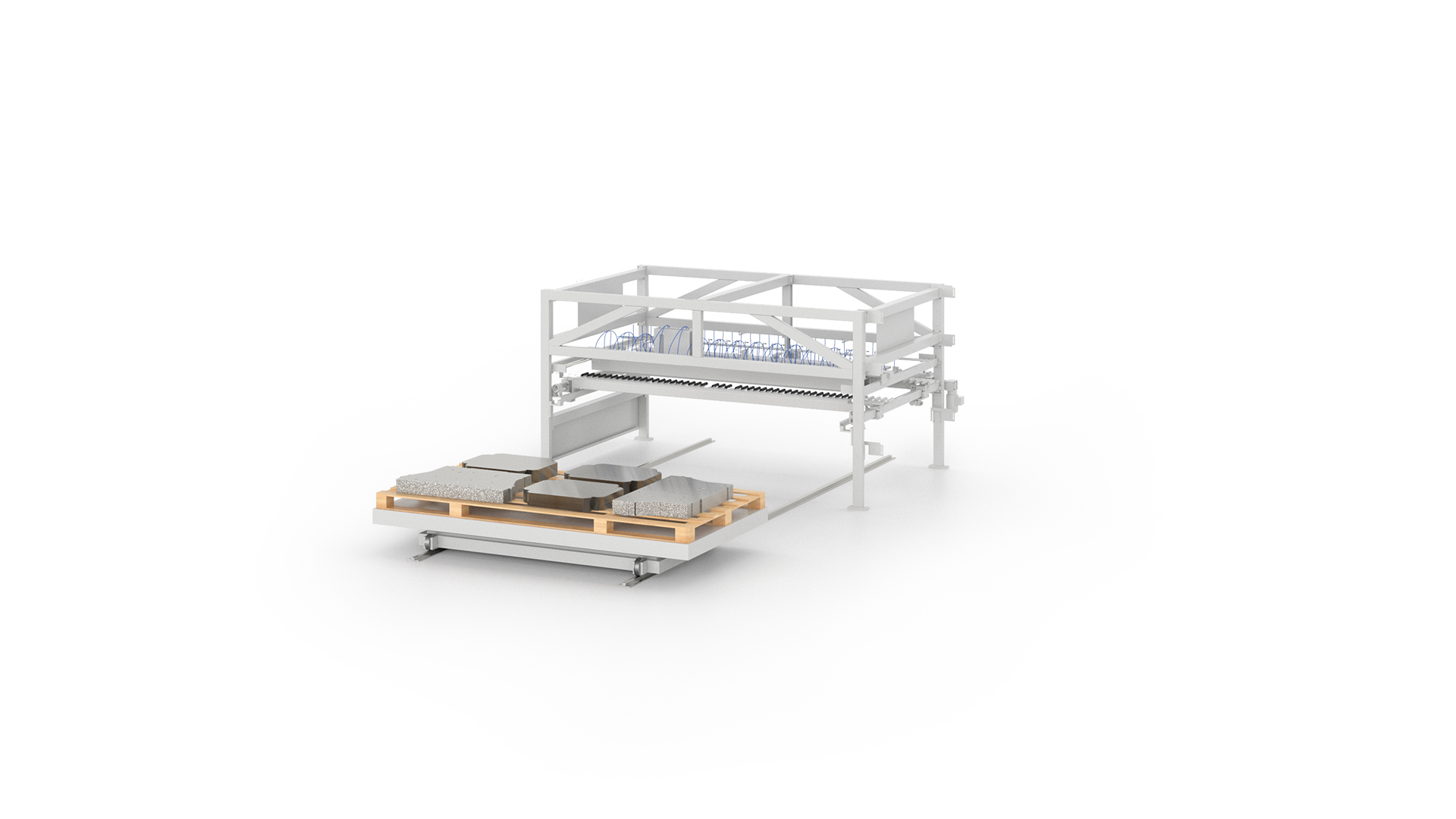

Storage and automatic loading/unloading devices increase the autonomy of the system, regaining efficiency both in individual processing steps and throughout the production process. The wide range meets practically any layout or configuration requirements, adapting to the most diverse production strategies.

The S4 punching-shearing center maximizes process efficiency: all the loading, punching, forming, separation and unloading operations are automatic, done by a single system that eliminates semi-finished parts, does not require manual intervention and assures extreme repeatability.

The P4 uses universal bending tools which automatically adapt in-cycle to the panel geometry, without machine down times or manual retooling, allowing batch-one or kit productions.

The integrated adaptive technologies (advanced sensors, bending formula, MAC3.0) make the system intelligent and able to automatically adapt to changes in the material and the external environment, eliminating waste and corrections, and extending the range of products that can be made.

The P4 offers customized solutions, including auxiliary tools and additional devices for special geometries or different loading/ unloading solutions.

Product overview

The S4+P4 line operates completely automatically, from sheet loading to finished panel unloading, without operator intervention. It ensures full repeatability, quality, and productivity by integrating automation, adaptive technologies, and advanced software for safe, lights-out manufacturing.

The S4+P4 line guarantees a continuous and fast production flow, minimizing through-times and eliminating work-in-progress. Thanks to integrated automation and line intelligence, it ensures high takt time, optimized performance, and efficient use of resources with no intermediate handling.

The S4+P4 line supports various production strategies—including Make To Order (MTO), Make To Stock (MTS), batch-one, and medium or large batches—automatically adjusting workflows, resources, and machine synchronization to maximize productivity and minimize waste.

Line intelligence continuously monitors and balances workloads across stations. It autonomously manages availability and buffering, optimizing flow and preventing bottlenecks, ensuring both the S4 and P4 operate at peak efficiency under any production condition.

Ideal for highly variable or complex parts, the system manages parametric production by adapting to different sizes, materials, and nesting layouts. It enables just-in-time, kit-based production with reduced setup times and high levels of flexibility and precision.

The S4+P4 line is highly configurable, integrating the whole range of Salvagnini automations. The Salvagnini loading/unloading and sorting connections satisfy all automation requirements: from stand-alone operation, to integration in flexible cells or in automatic lights-out factories.

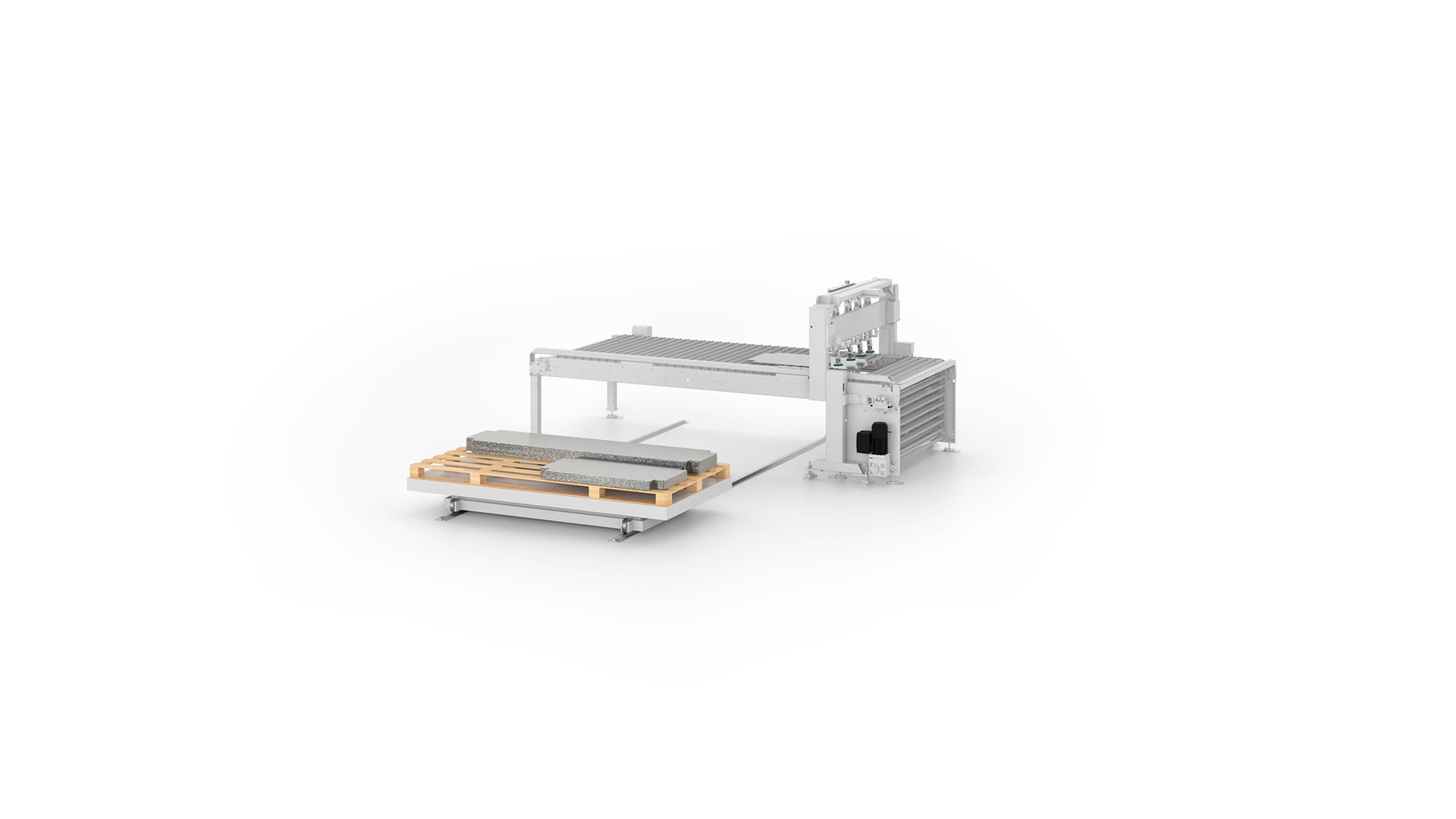

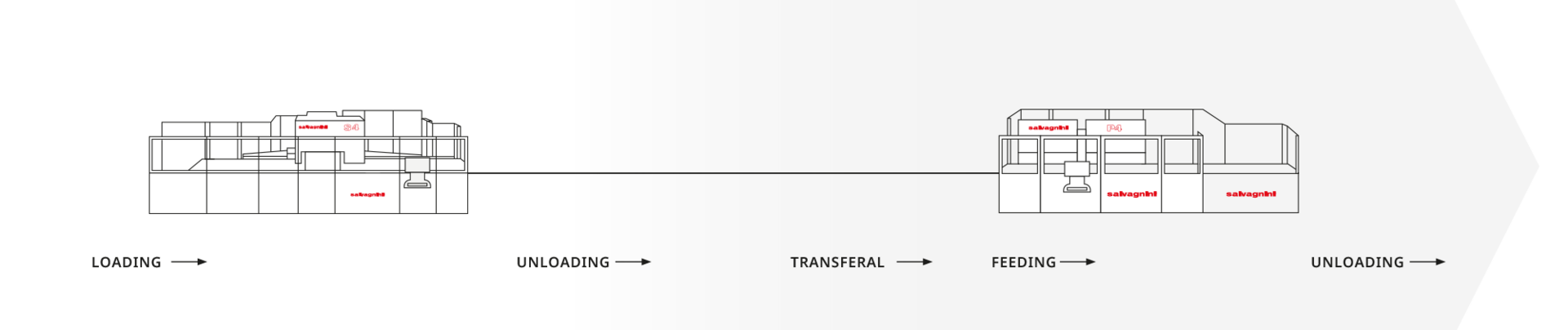

Feeding devices

Salvagnini supplies different types of feeding connections: from the in-line conveyor to the automatic destacker, from the automatic store with single tower to the automatic multi-tower tray store.

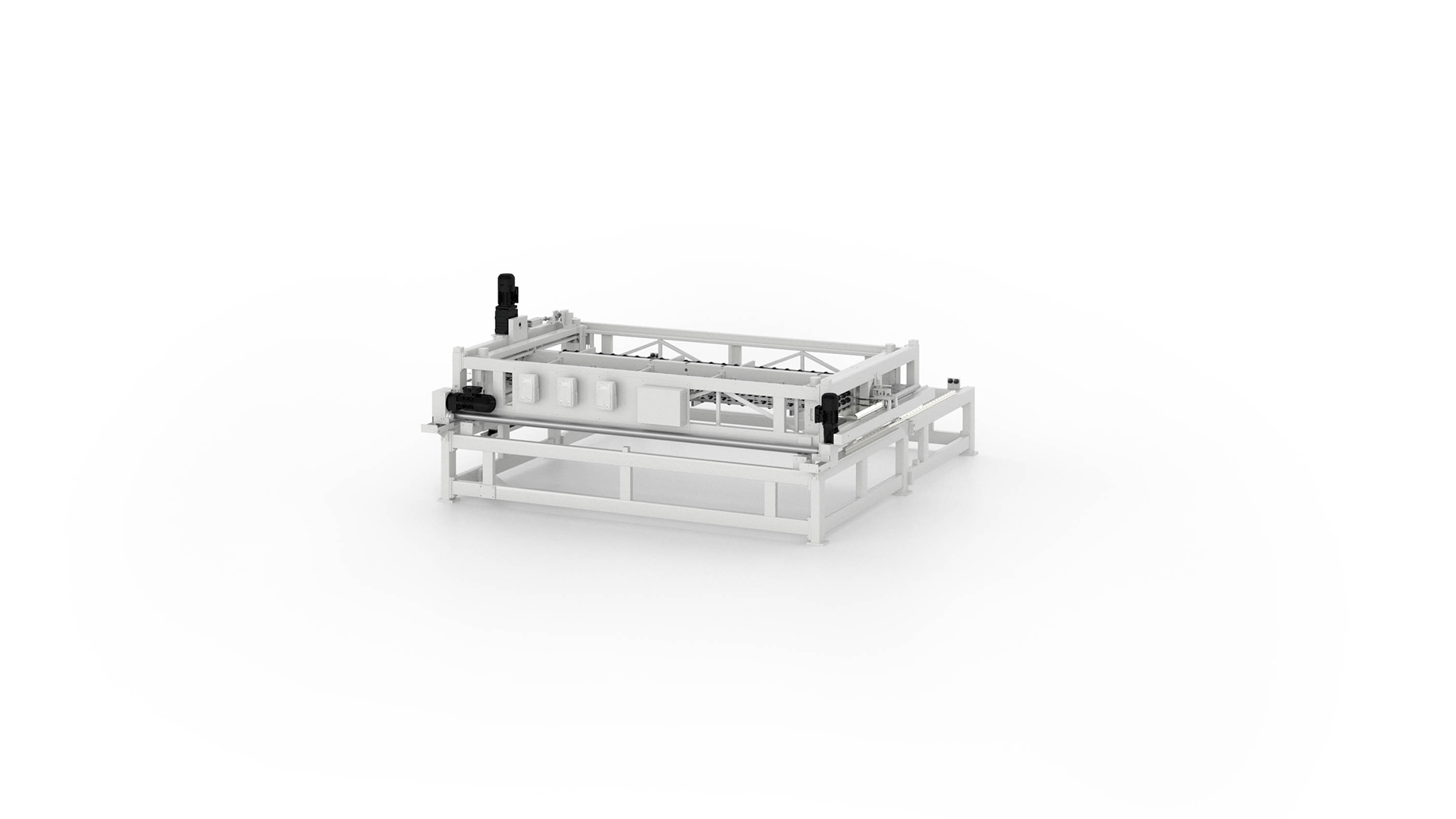

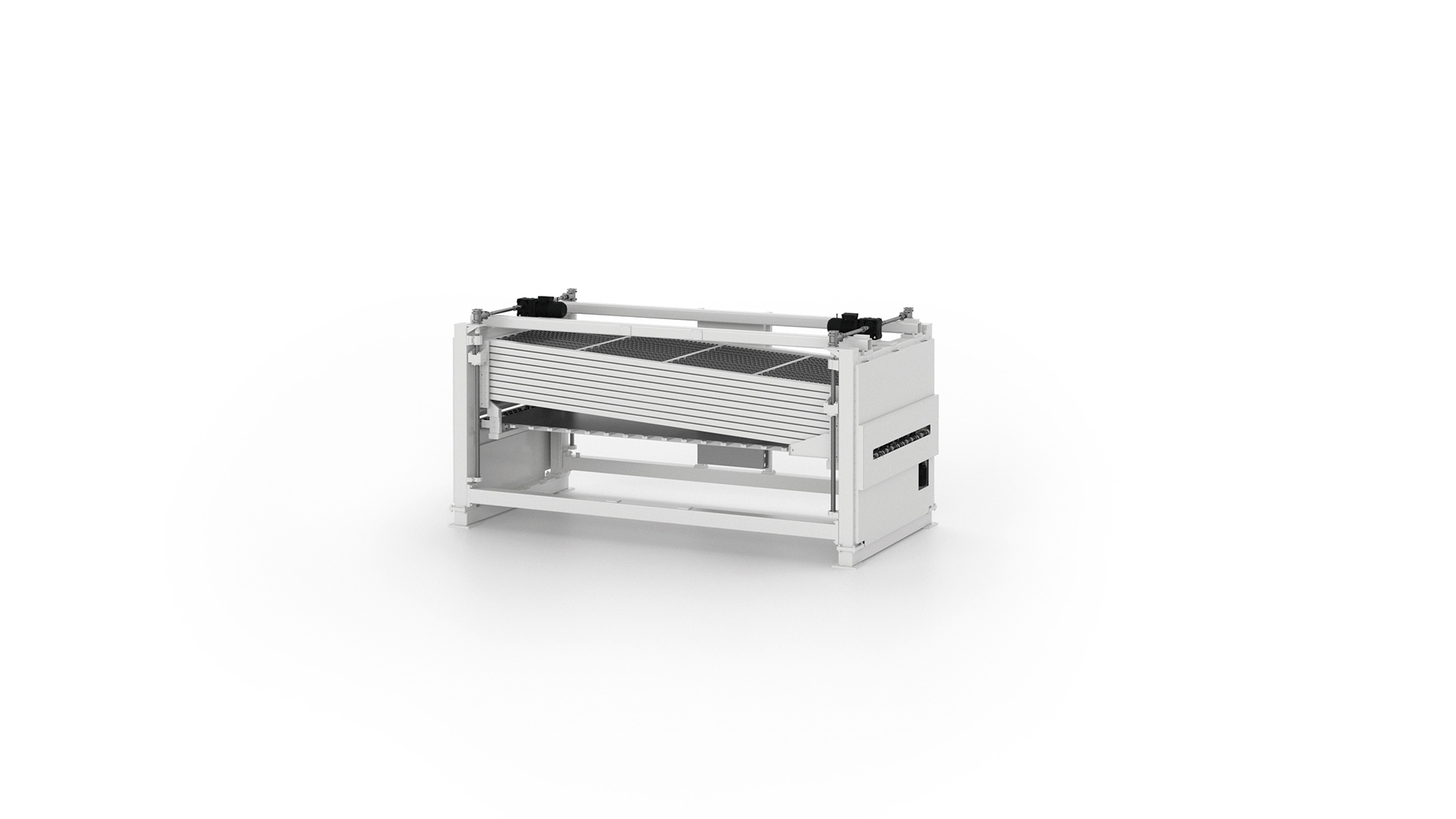

Transfer devices

The line components also include sheet metal transfer and turning devices.

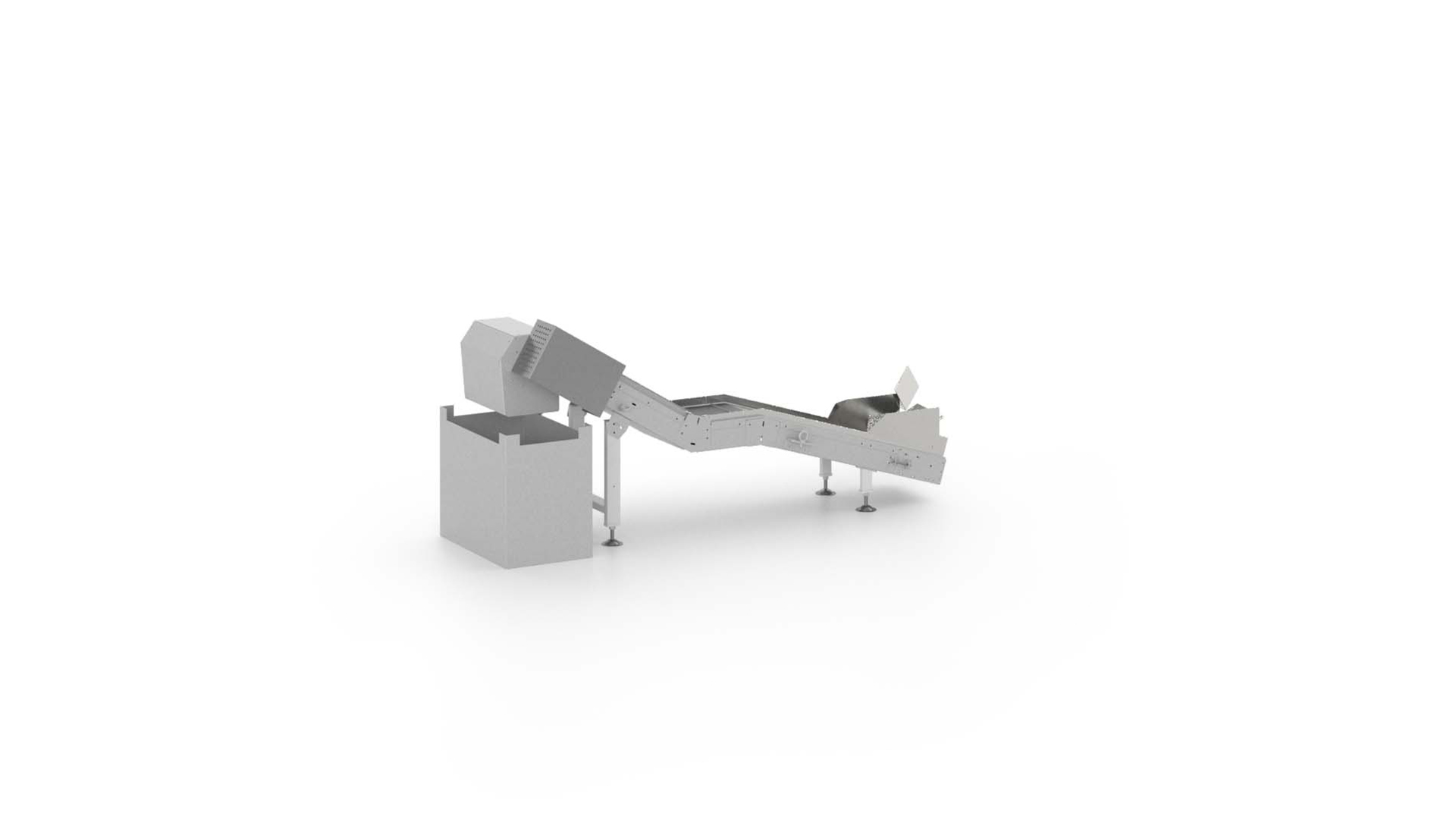

Loading/unloading devices

The punched and/or sheared parts can be automatically directed to collection bins, buffers, one or more stackers, intermediate stores, or straight to downstream operations. The bent panels can be unloaded by different manual or robotic unloading devices.

MAC3.0

MAC3.0 detects any differences in the mechanical characteristics of the material compared to their nominal value during the cycle, adapting the movements of the bending unit and the manipulator to compensate them.

Industry 4.0

Digital transformation and Industry 4.0 are key topics for staying competitive on the market. When adopted, they can implement and manage complex, integrated, highly automated high-performance systems, and can help to develop simple solutions that require no structural changes to the production layout, making the world of smart manufacturing much more accessible.

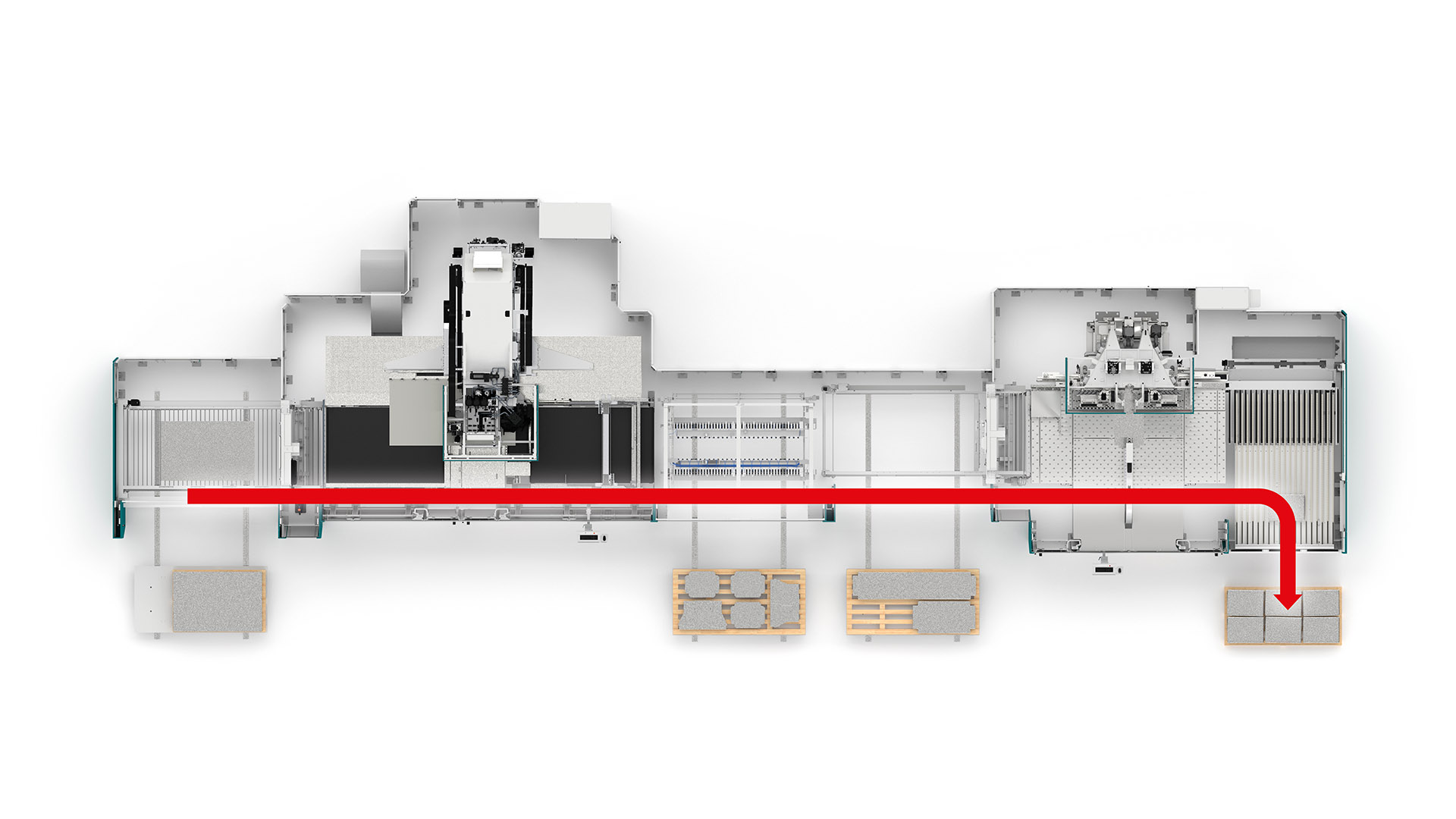

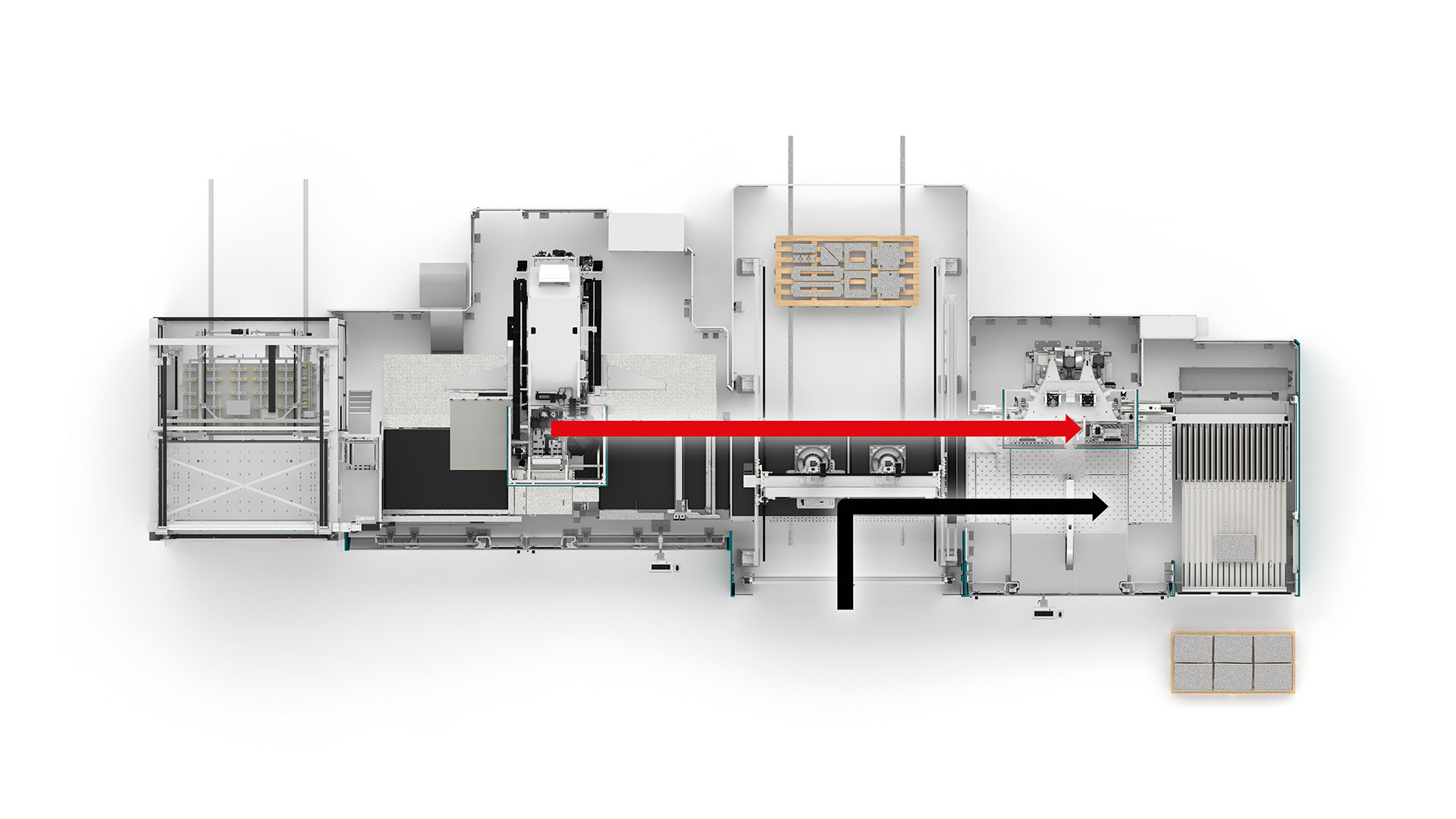

In line

It is direct production flow, in which the sheet metal is loaded, punched, separated, transferred, bent and unloaded. It is the strategy for producing, from raw sheet metal to finished panel, what is needed when it is needed, completely automatically and without any work in progress, fully in line with the lean philosophy.

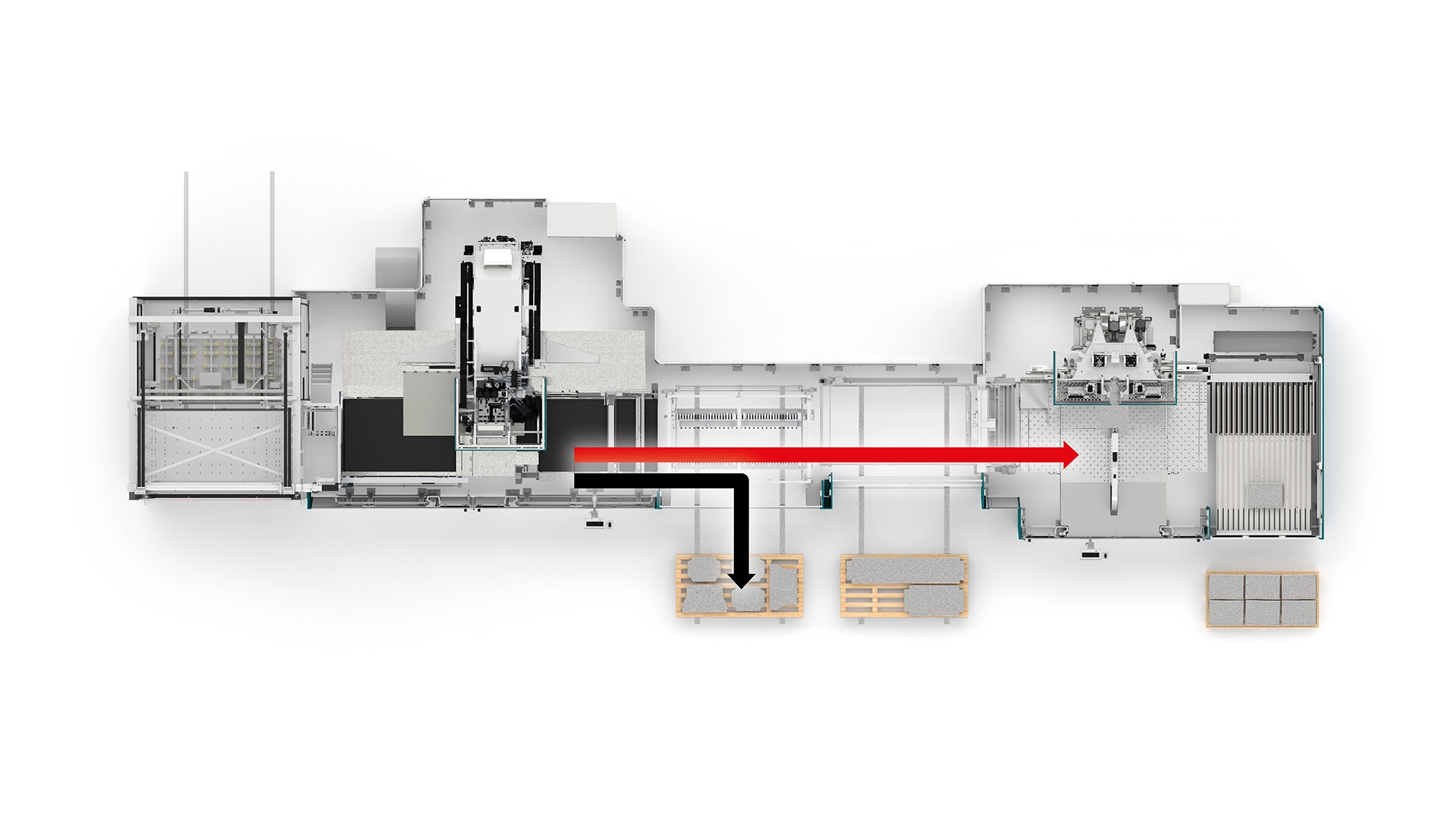

Standalone

S4 and P4 work independently. The sheet metal is loaded onto the S4, punched, separated and unloaded. In the same way, the sheet metal can be loaded onto the P4, bent and unloaded. This strategy doubles the line potential by making available two systems which, when not working synchronously, work as different and independent technologies.

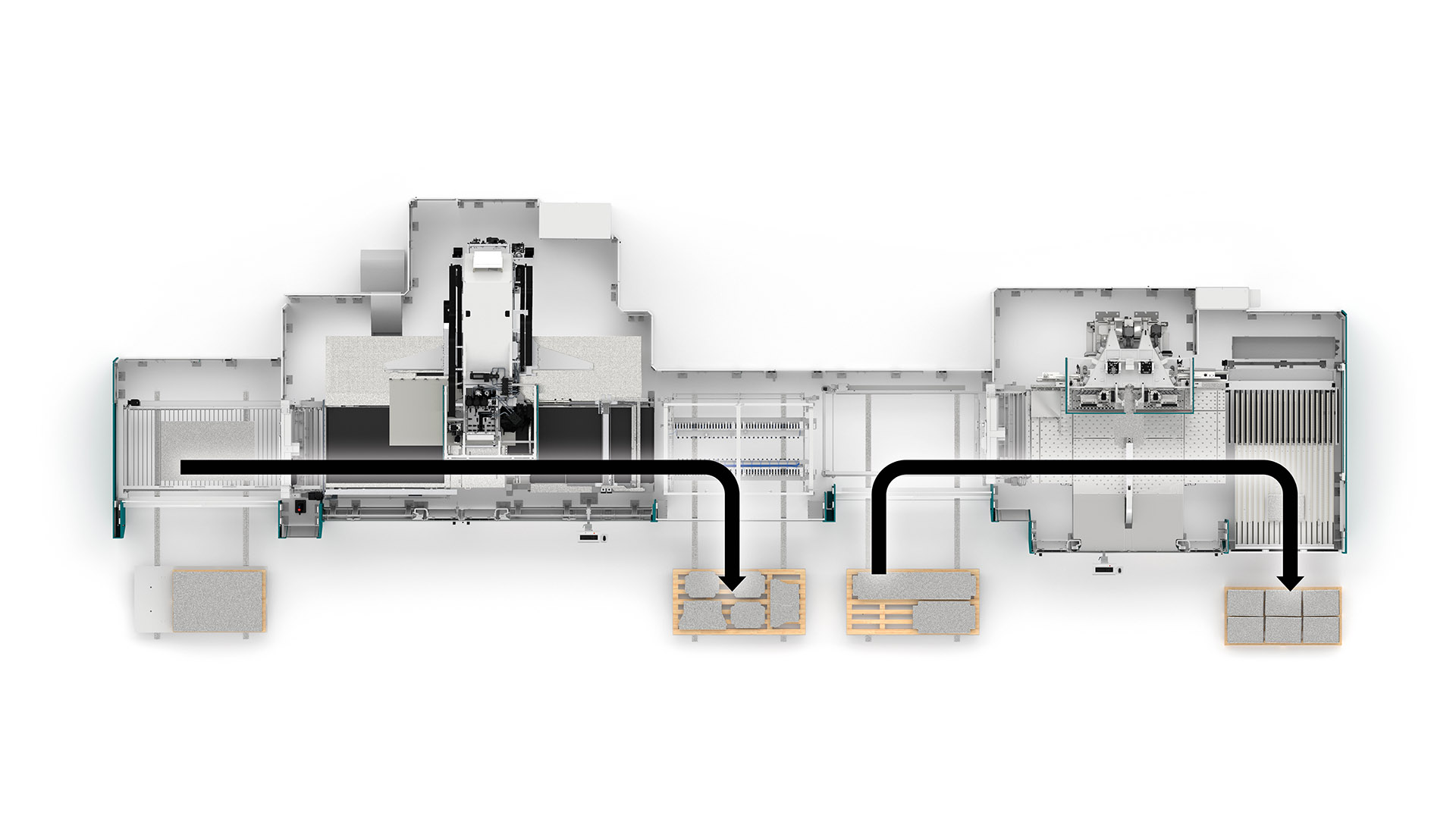

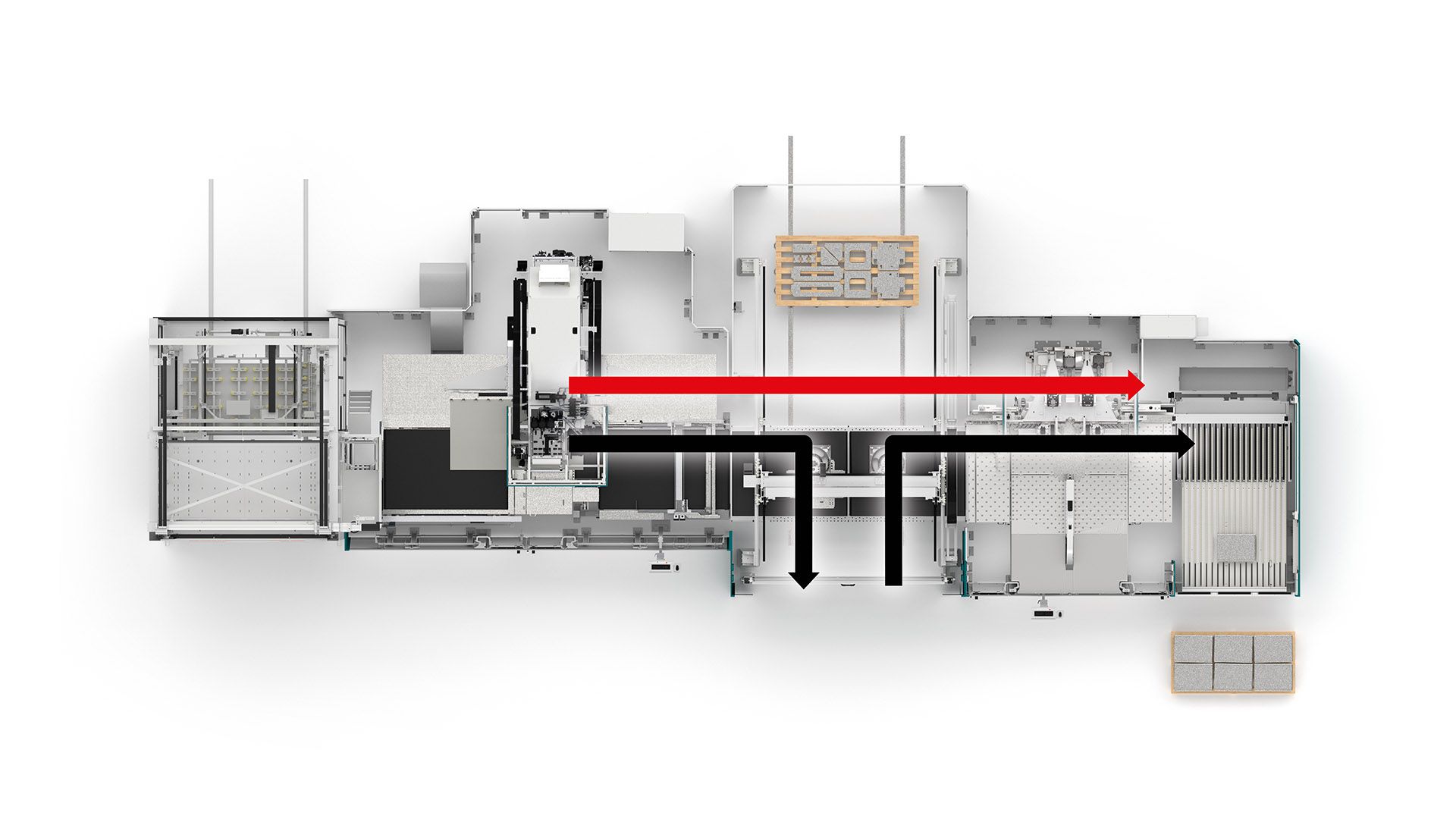

Stack

The stack mode strategy maximizes the S4 productivity. The S4 feeds the P4 but does not wait for the P4 to be available for subsequent parts: it continues to punch and separate the parts, which are unloaded to feed other workstations and the semi-finished part store. As soon as the P4 is available again, the system returns to in line production and the S4 feeds the panel bender once more.

Pack

The pack mode strategy maximizes the P4 productivity. If the P4 is available but the S4 hasn’t completed its jobs, the panel bender is fed by the PCD with already cut parts. As soon as the S4 is ready to send a part to the P4, the pack feeding is automatically stopped to allow the punched part passing through to be bent.

Dynamic

Dynamic buffering assures a truly independent system in terms of balancing. The line is able to independently decide what to do: when the P4 is busy, the parts arriving from the S4 are automatically parked in the waiting position; when the P4 is available and the S4 is not able to feed it, the parts in the waiting position are automatically recovered and produced. The line intelligence automatically manages dynamic buffering: it optimizes the productivity of both machines without adding constraints to the nest programming, giving priority to line jobs, optimizing a specific work flow to facilitate other downstream operations on the line such as assembly. Dynamic buffering requires the MCU automatic sorting device to be placed between the S4 and the P4.

Most frequest sectors and configurations

S4 | P4 | SMD | IA | MCU | ACP | PCD | RIP | SAP | |

| HVAC | ● | ● | ● |

|

| ● |

|

| ● |

| Doors | ● | ● | ● | ● |

| ● |

|

| ● |

| Electrical industry | ● | ● | ● |

| ● |

|

| ● | ● |

| Lifts/elevators | ● | ● | ● | ● |

| ● |

| ● | ● |

| Ho.Re.Ca. | ● | ● | ● | ● |

|

| ● | ● | ● |

| Construction | ● | ● | ● |

| ● |

| ● | ● | ● |

| Subcontracting | ● | ● | ● |

| ● |

| ● | ● | ● |

| Steel furniture | ● | ● | ● |

| ● |

| ● | ● | ● |

Trusted by manufacturers: hear their experience

Løgstrup | Denmark

Løgstrup, a Danish leader in switchboards and modular enclosures, boosted its production with a fully automated Salvagnini line. Equipped also with ACF cornerformers, this S4+P4 ensures precise, weld-free corner forming while minimizing manual work. End-to-end automation and OPS software streamline workflows, enabling Løgstrup to deliver high-quality modular panels for the growing electrical and green energy sectors.

MingYang Electric | China

MingYang New Energy, a leading Chinese manufacturer of intelligent electrical equipment, enhanced its production with a Salvagnini S4+P4 automated line. This smart FMS cut operators from six to two, improved material utilization to nearly 90%, and streamlined workflows for greater efficiency. Backed by reliable support and fast service, this investment strengthened MingYang’s capabilities while reinforcing its commitment to innovation and customer satisfaction.

Henke | Germany

Henke GmbH, a German specialist in sheet metal working, expanded its capabilities with a Salvagnini S4+P4 line. This fully automated system exceeded expectations by combining high speed with low unit costs. With its high level of automation, Henke now produces larger volumes in shorter times while improving cost efficiency.

Wippro | Austria

Wippro GmbH, an Austrian specialist in attic stairs, roof hatches, and wooden doors, has relied on Salvagnini technology since 1998. With its S4+P4 line, integrated with a store tower and stacking robot, the company now punches, bends, and sorts components fully automatically. This highly flexible system enables economical batch size 1 production, boosting efficiency and adaptability.

NAD | Emirates

NAD Group, a leading furniture manufacturer with operations in the UAE and Turkey, transformed its production with a Salvagnini S4+P4 line. This FMS streamlined processes, enabling next-day delivery for custom orders and significantly boosting efficiency. Supported by Salvagnini’s advanced technology and reliable service, NAD Group strengthened its competitiveness and positioned itself for future growth.

Pramac | Spain

Pramac Ibérica, Spanish manufacturer of power generators, enhanced its production with a Salvagnini fully automated S4+P4 line. This FMS increased flexibility, precision, and safety while cutting costs and lead times. As a result, Pramac Ibérica now produces 15% faster and has expanded capacity by 40%.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the line. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Ready to dive in?