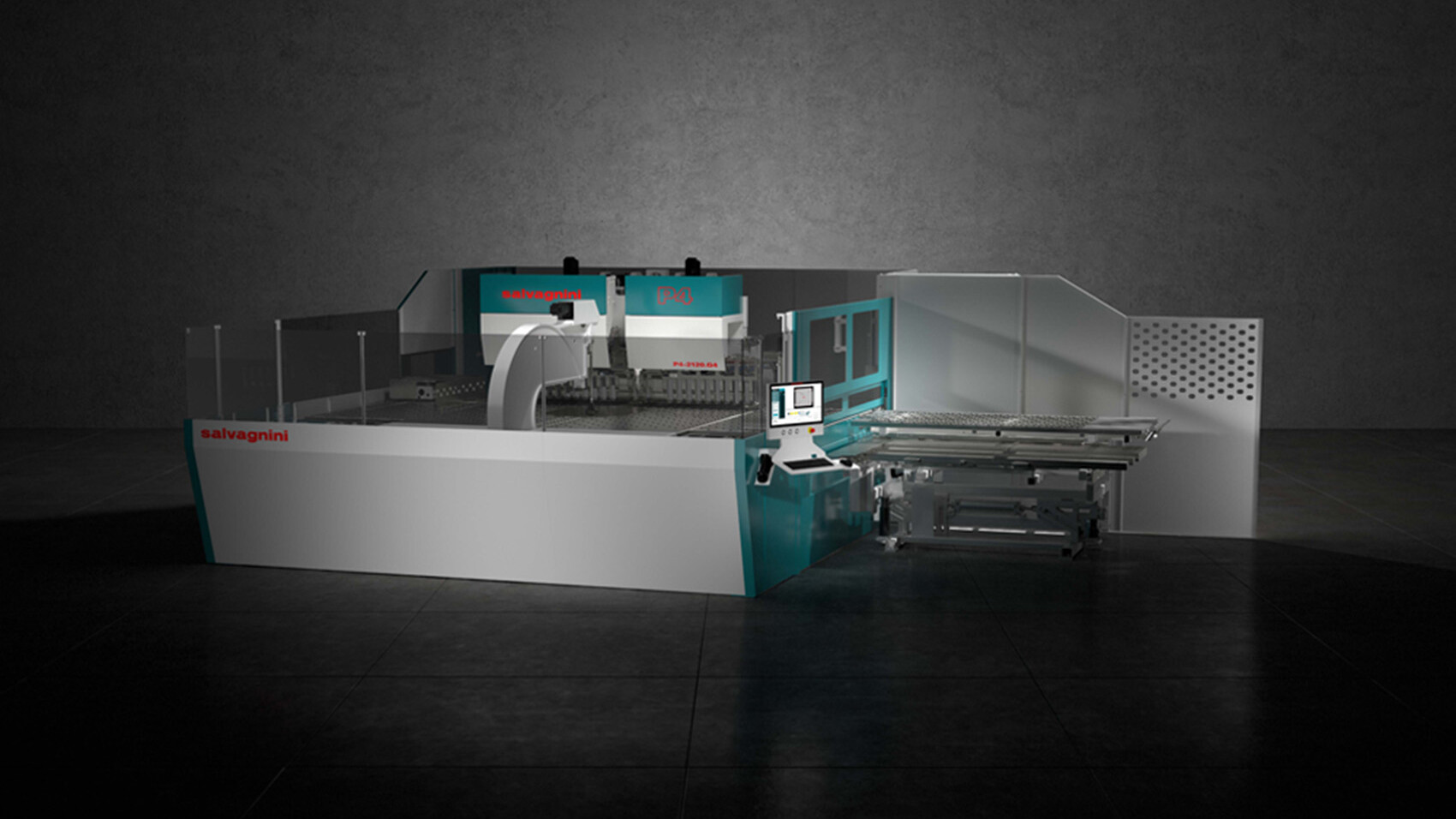

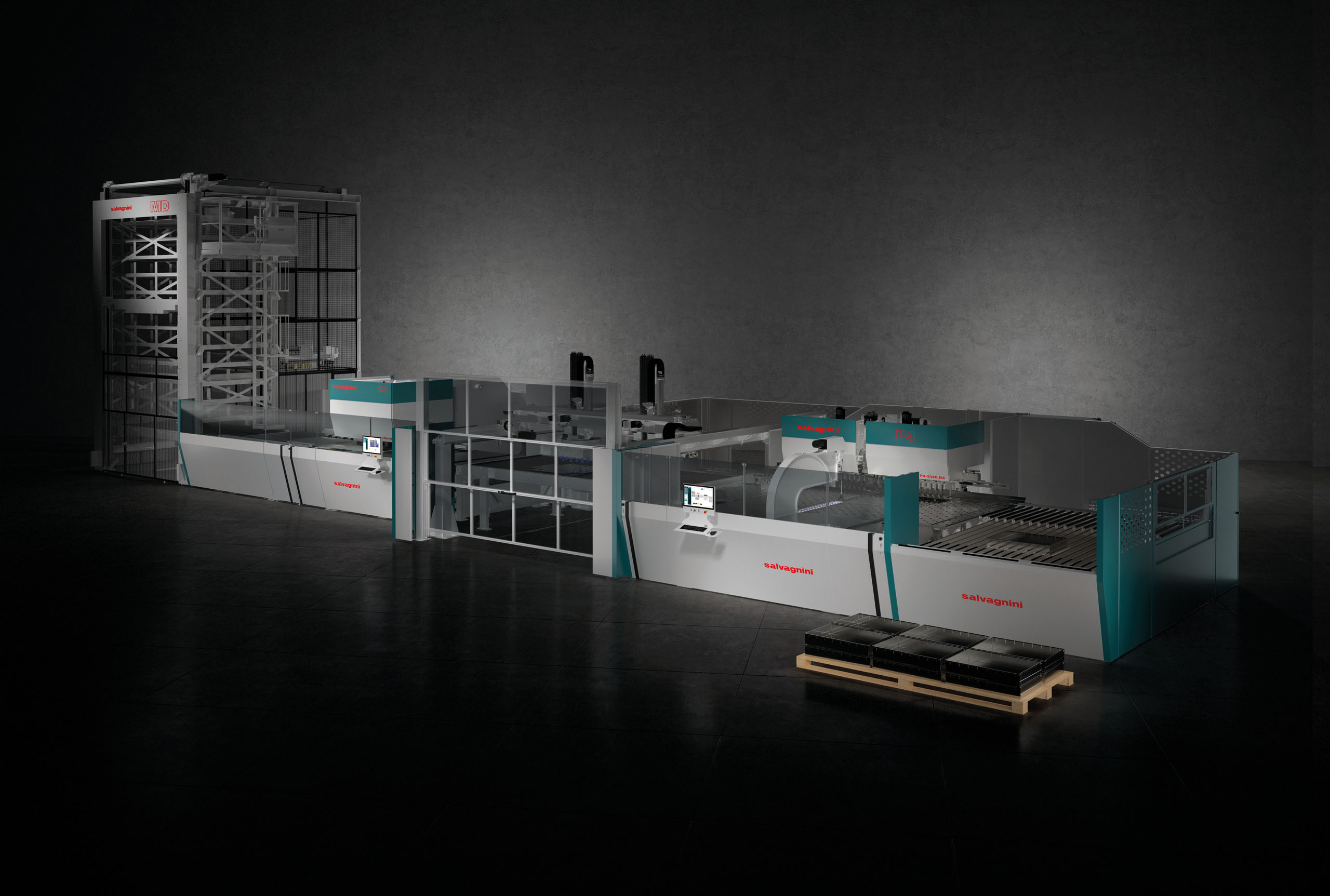

FMS Line

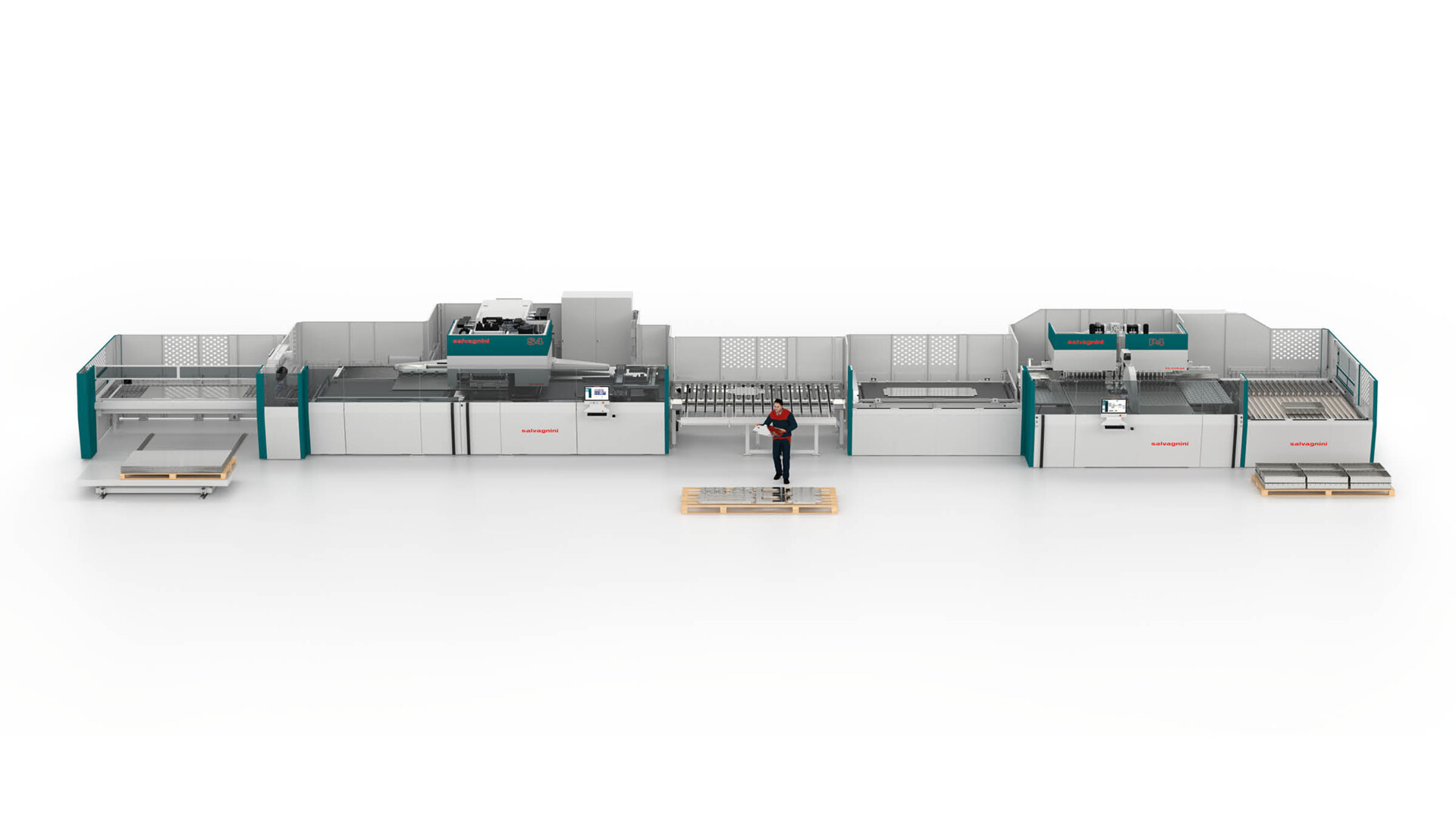

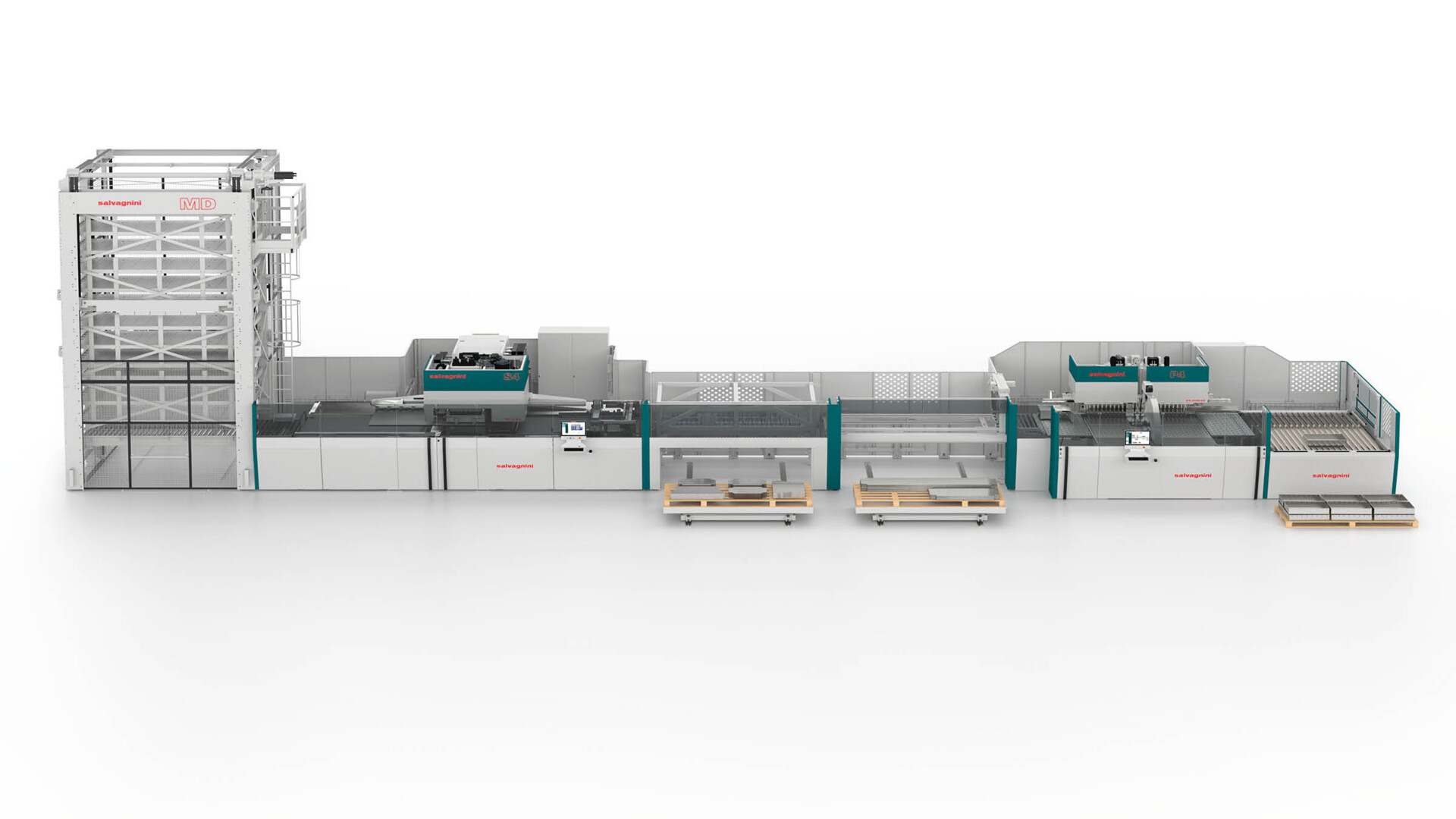

The S4+P4 line ensures continuous production of kits and batch ones, minimizing cycle times, semifinished parts and intermediate handling, eliminating tool changes.

Fast-flow jobs, 100% guaranteed

The parts, from raw material to bent panel, cross through all the work stations continuously and in a short time, minimizing through-times and optimizing performance. The line intelligence, that knows the processing and through-times of parts and machinery, autonomously manages the station availability, optimizing the result according to the production strategy.

Product overview

The S4+P4 line operates completely automatically, from sheet loading to finished panel unloading, without operator intervention. It ensures full repeatability, quality, and productivity by integrating automation, adaptive technologies, and advanced software for safe, lights-out manufacturing.

The S4+P4 line guarantees a continuous and fast production flow, minimizing through-times and eliminating work-in-progress. Thanks to integrated automation and line intelligence, it ensures high takt time, optimized performance, and efficient use of resources with no intermediate handling.

The S4+P4 line supports various production strategies—including Make To Order (MTO), Make To Stock (MTS), batch-one, and medium or large batches—automatically adjusting workflows, resources, and machine synchronization to maximize productivity and minimize waste.

Line intelligence continuously monitors and balances workloads across stations. It autonomously manages availability and buffering, optimizing flow and preventing bottlenecks, ensuring both the S4 and P4 operate at peak efficiency under any production condition.

Ideal for highly variable or complex parts, the system manages parametric production by adapting to different sizes, materials, and nesting layouts. It enables just-in-time, kit-based production with reduced setup times and high levels of flexibility and precision.

The S4+P4 line is highly configurable, integrating the whole range of Salvagnini automations. The Salvagnini loading/unloading and sorting connections satisfy all automation requirements: from stand-alone operation, to integration in flexible cells or in automatic lights-out factories.

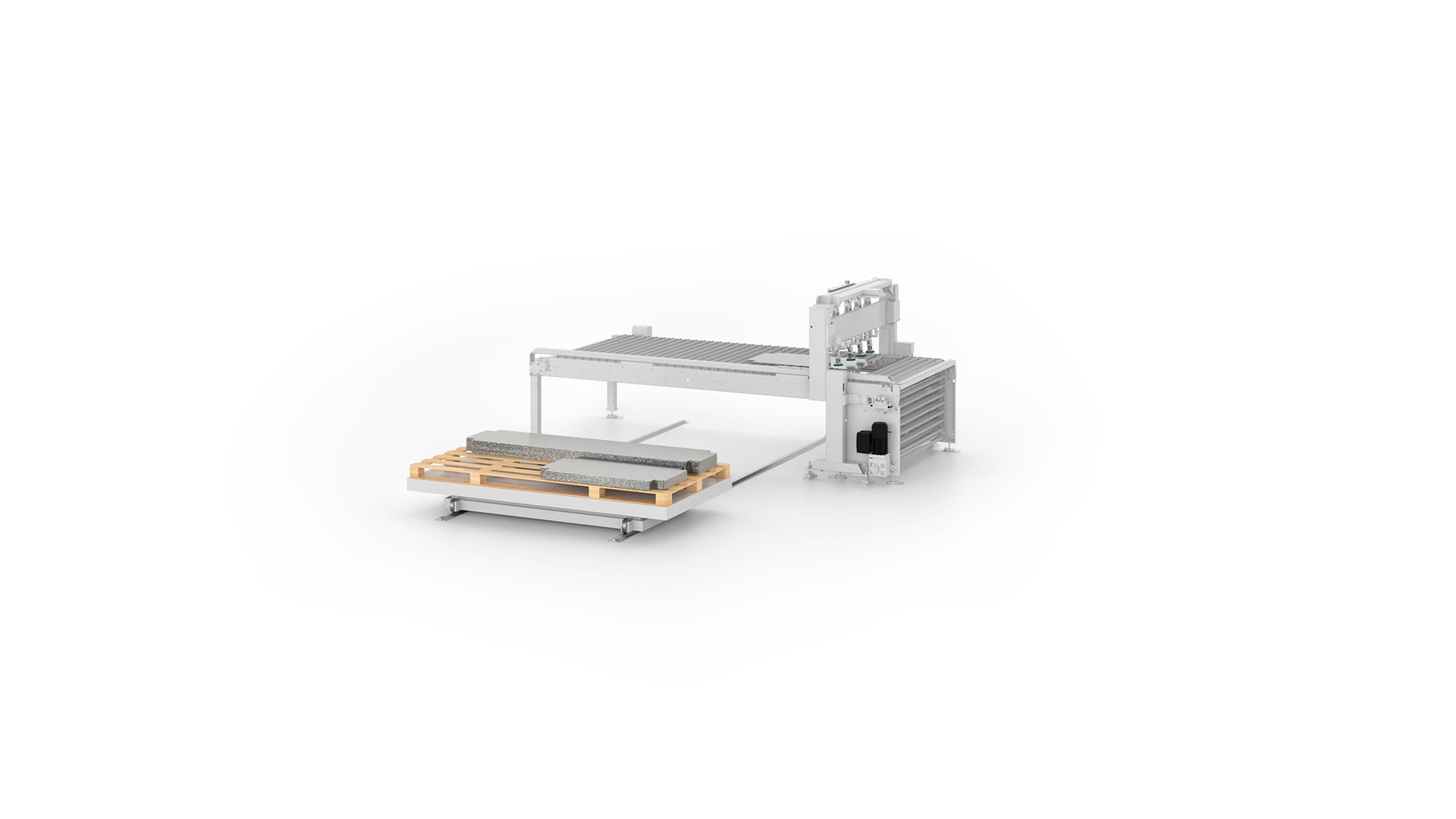

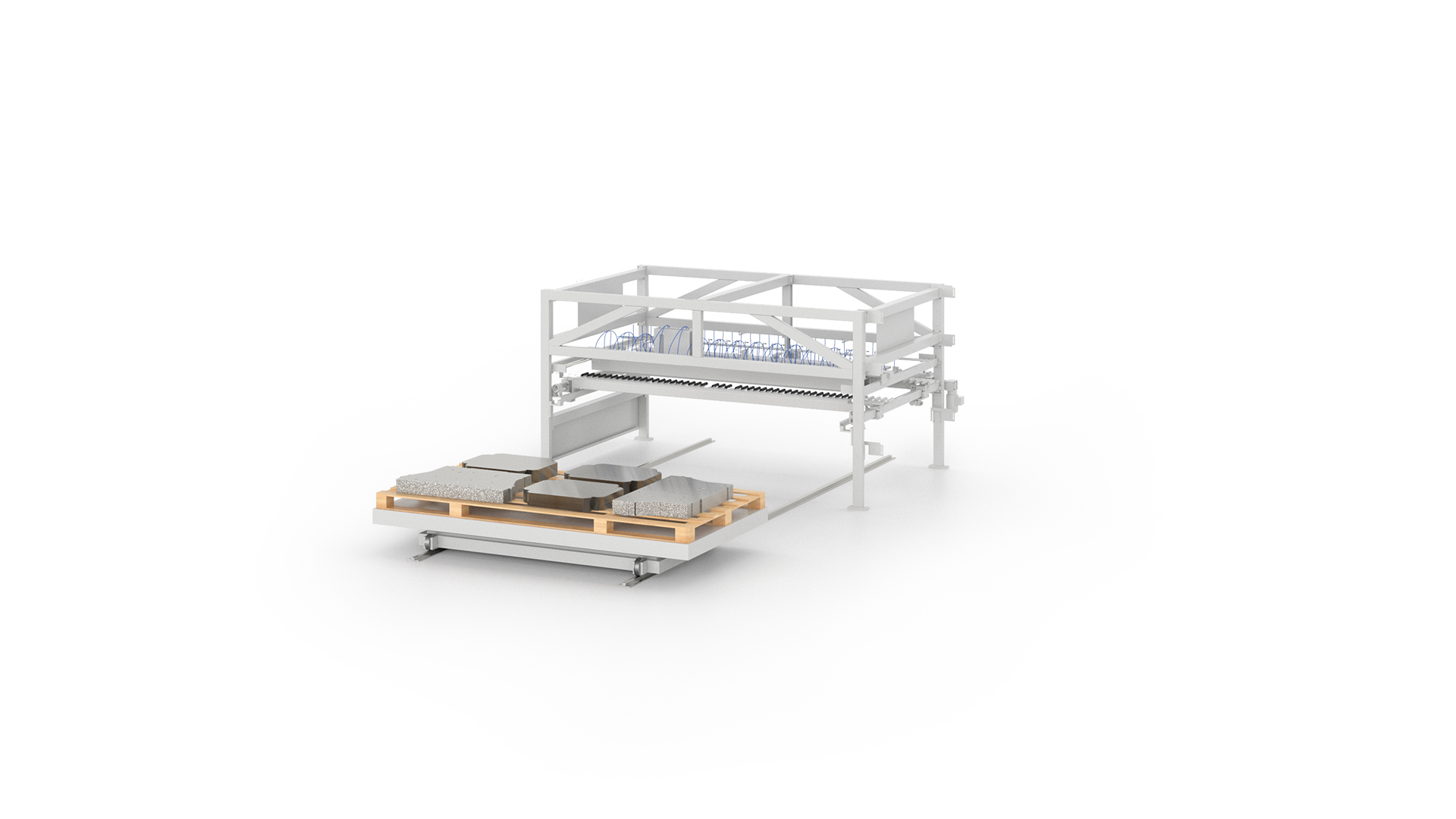

Feeding devices

Salvagnini supplies different types of feeding connections: from the in-line conveyor to the automatic destacker, from the automatic store with single tower to the automatic multi-tower tray store.

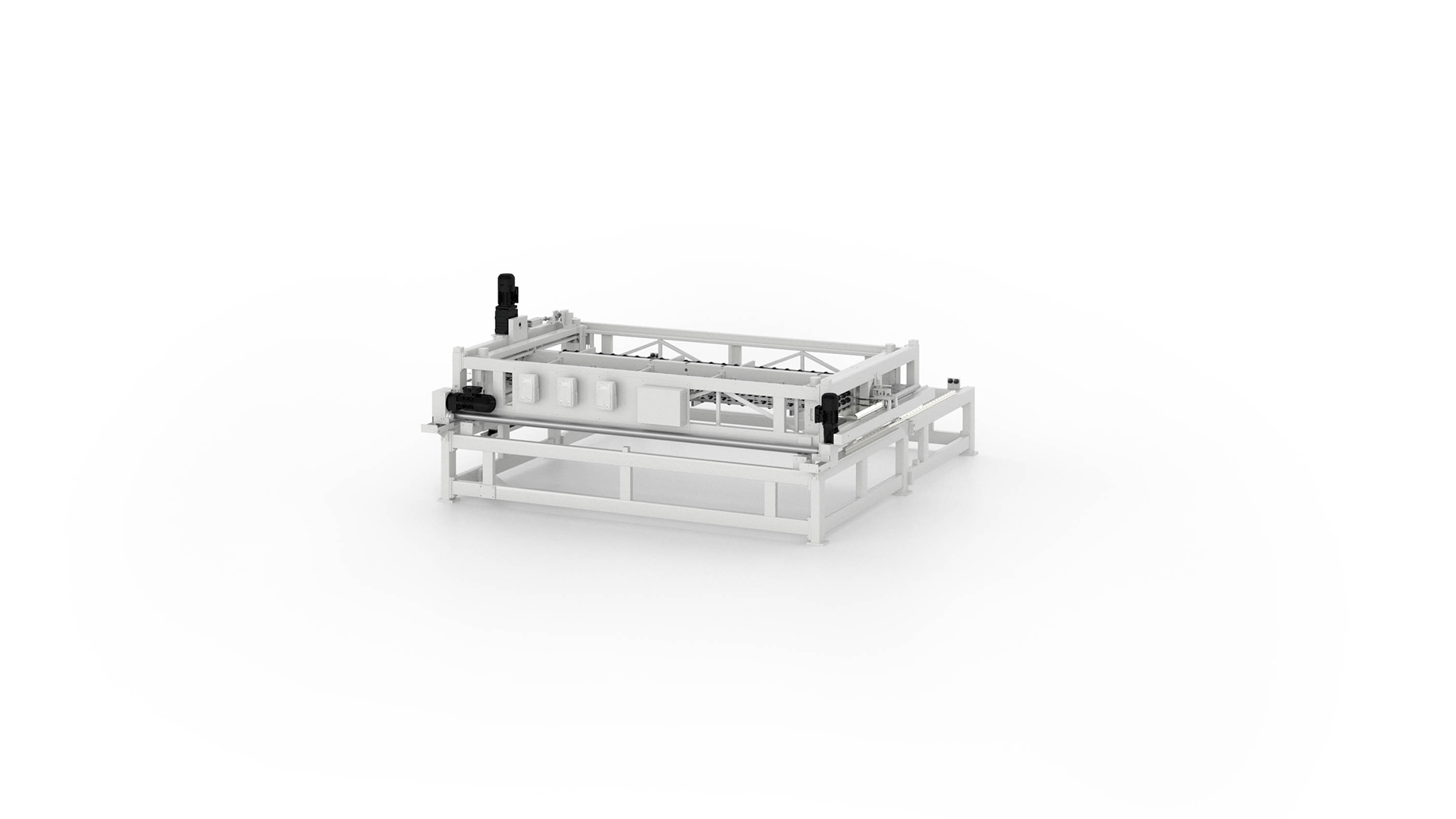

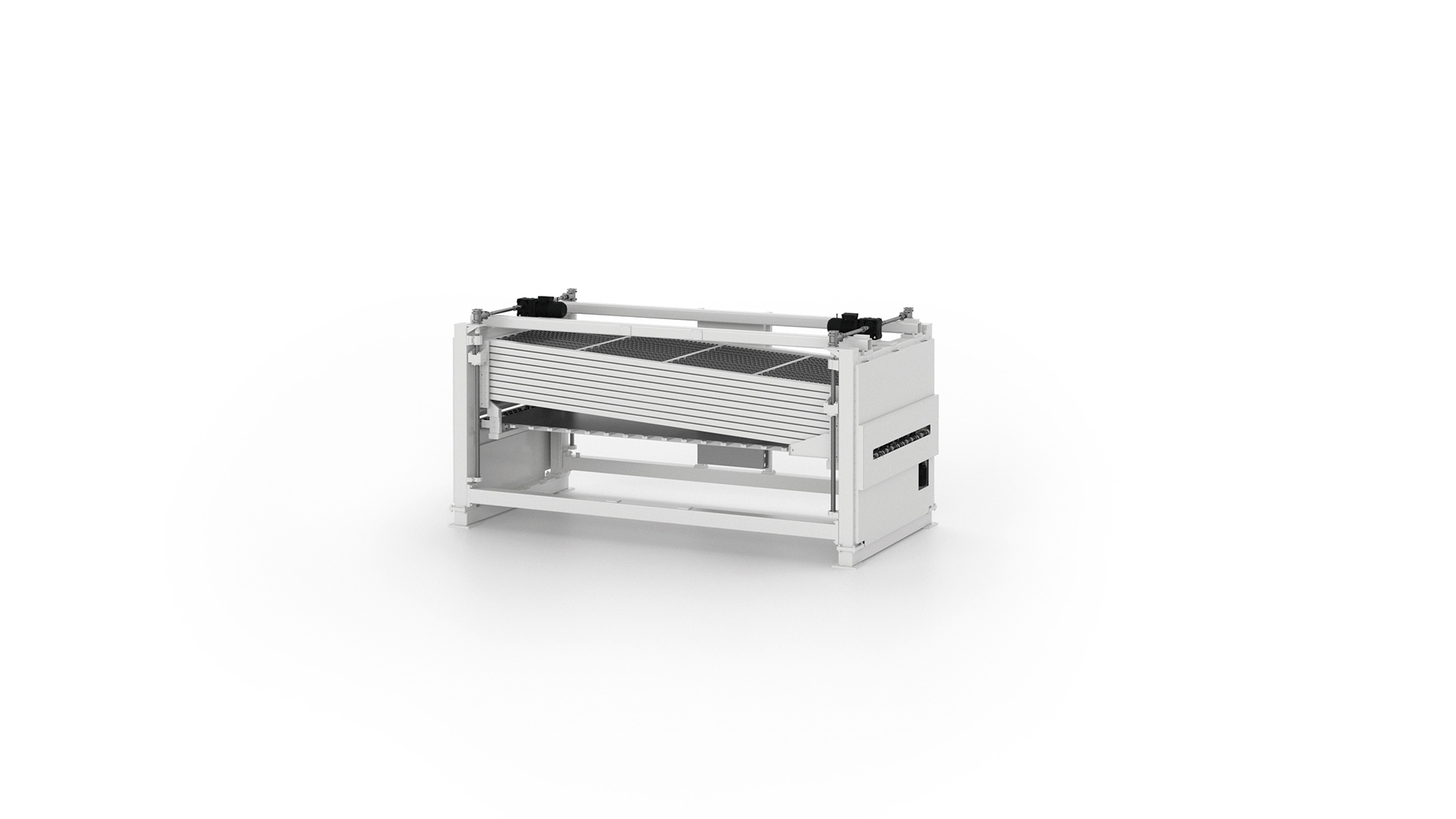

Transfer devices

The line components also include sheet metal transfer and turning devices.

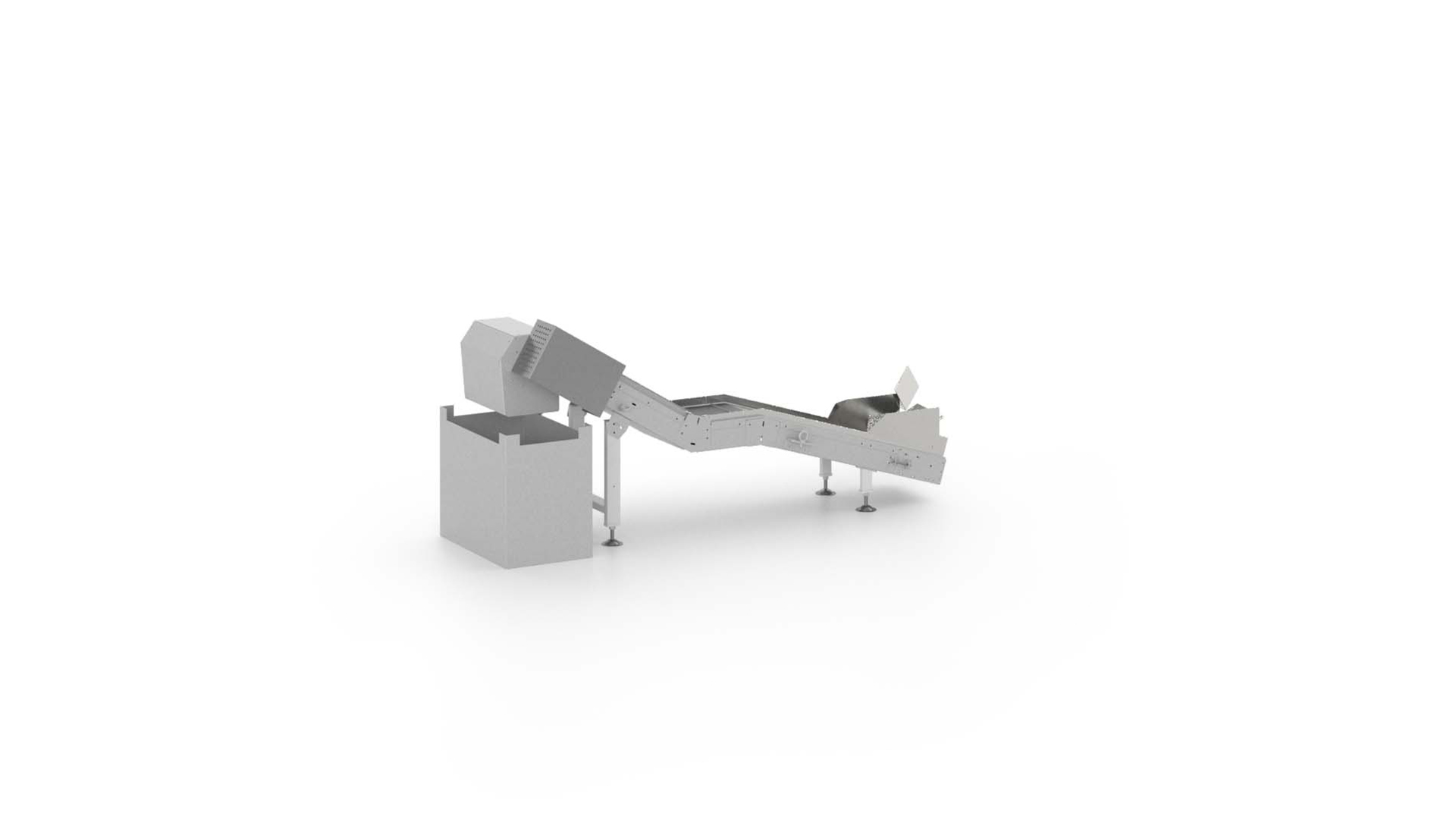

Loading/unloading devices

The punched and/or sheared parts can be automatically directed to collection bins, buffers, one or more stackers, intermediate stores, or straight to downstream operations. The bent panels can be unloaded by different manual or robotic unloading devices.

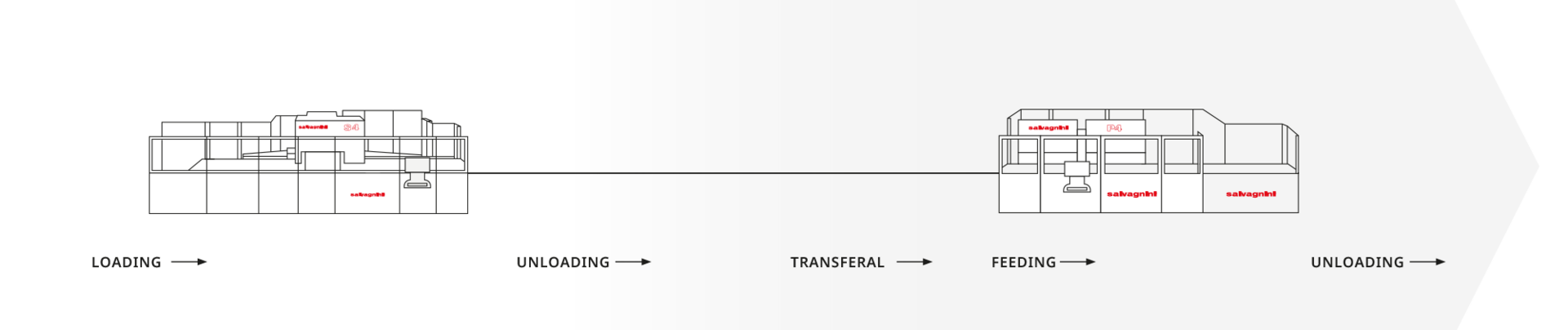

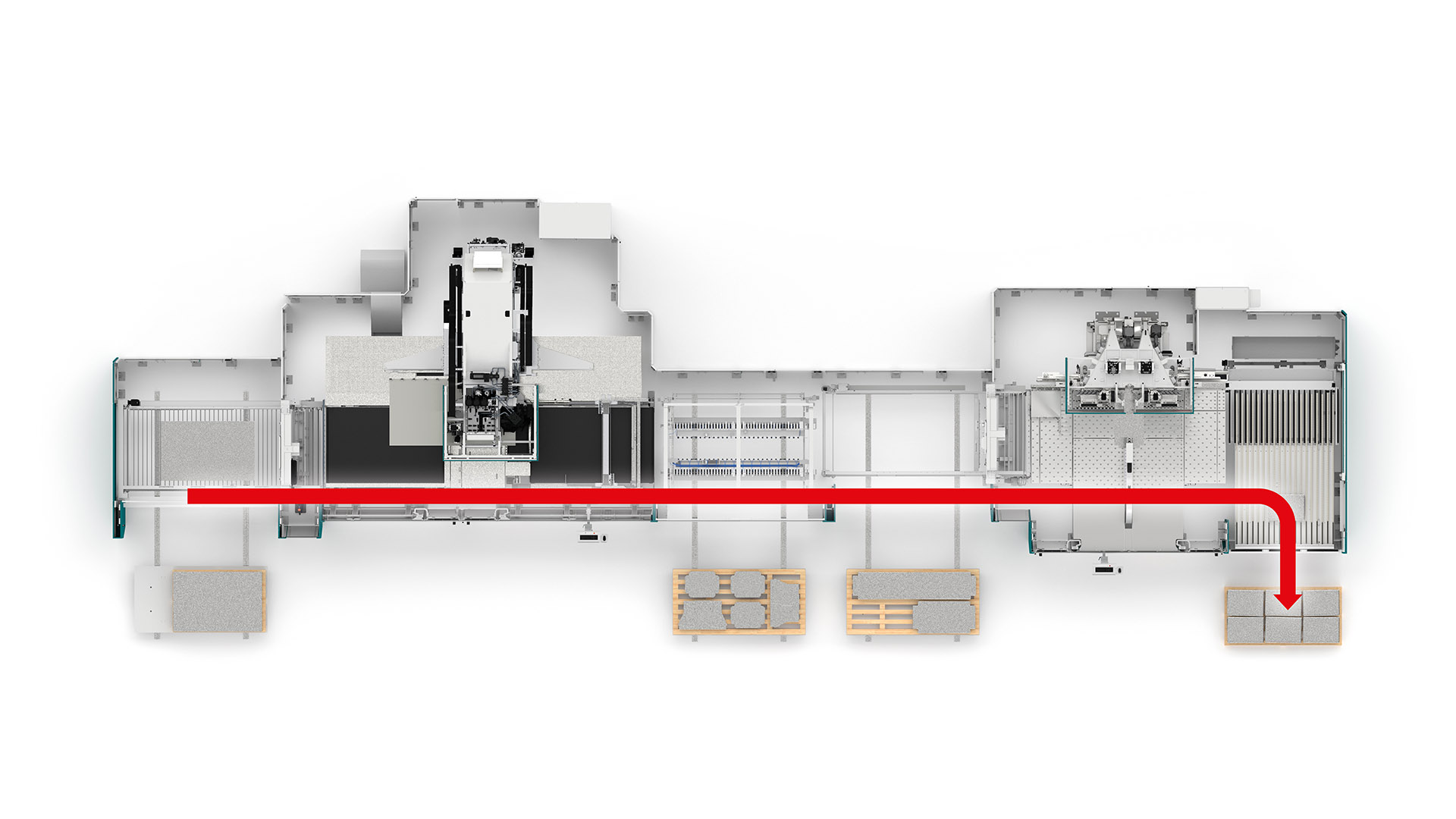

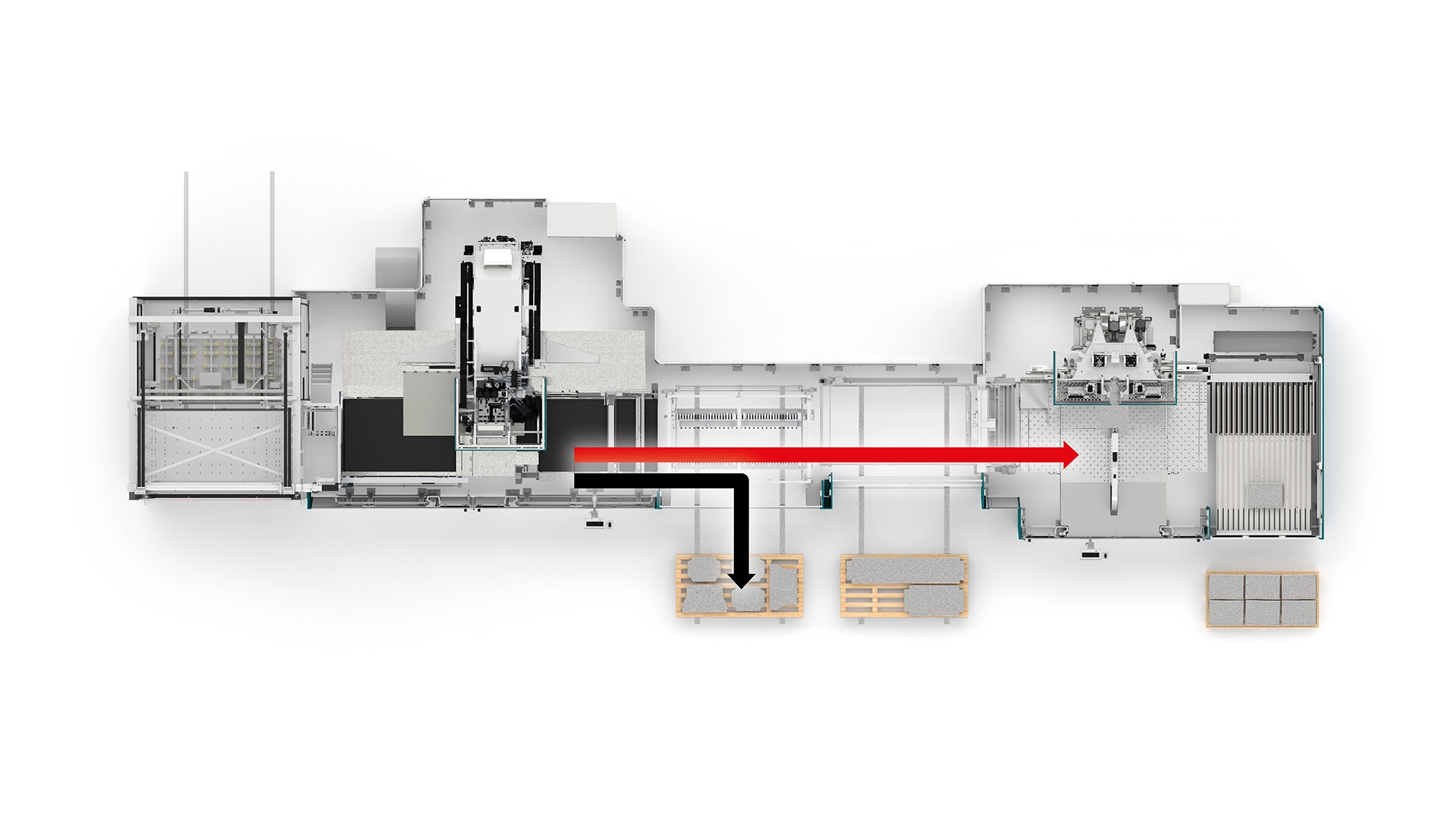

In line

It is direct production flow, in which the sheet metal is loaded, punched, separated, transferred, bent and unloaded. It is the strategy for producing, from raw sheet metal to finished panel, what is needed when it is needed, completely automatically and without any work in progress, fully in line with the lean philosophy.

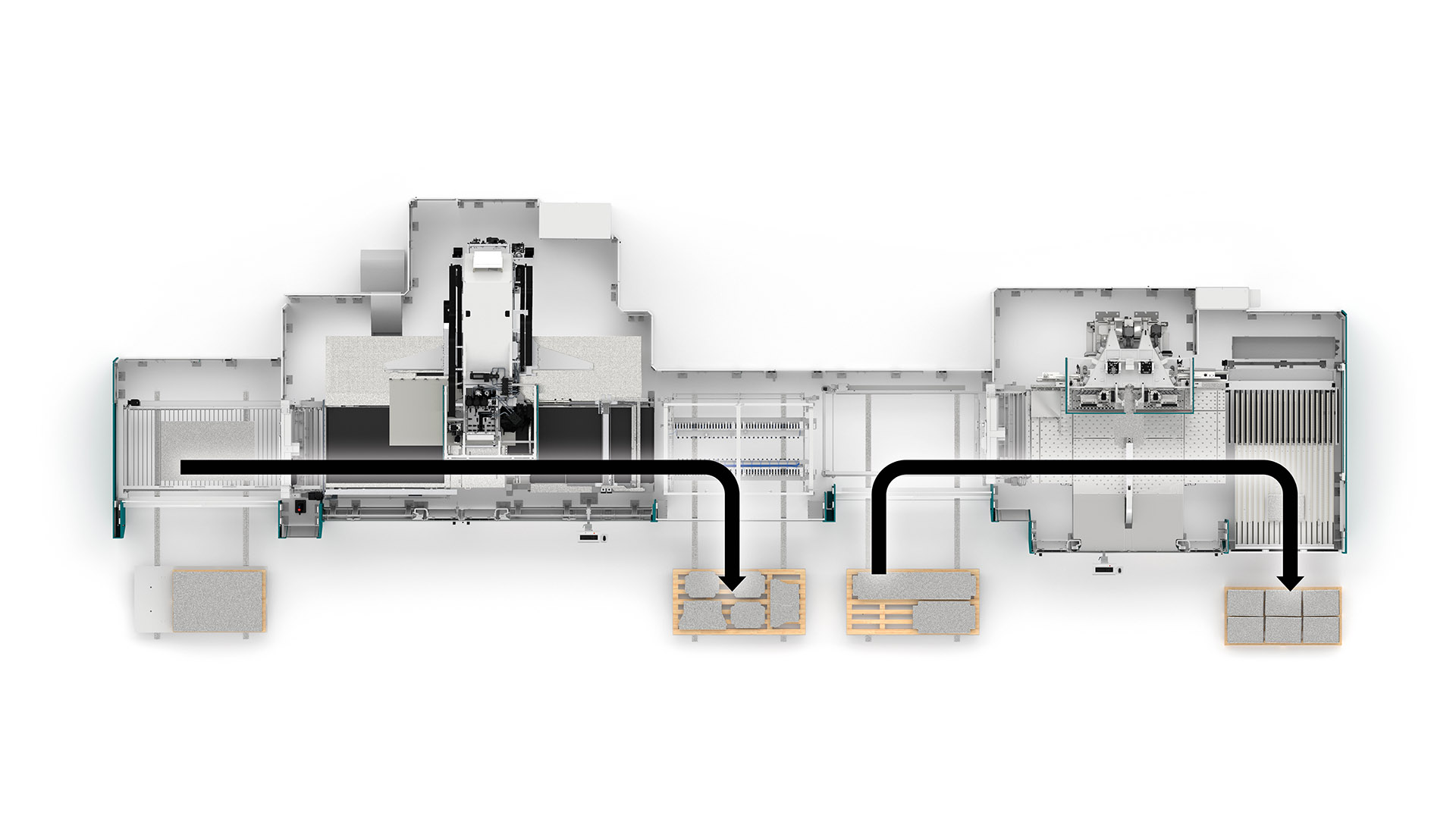

Standalone

S4 and P4 work independently. The sheet metal is loaded onto the S4, punched, separated and unloaded. In the same way, the sheet metal can be loaded onto the P4, bent and unloaded. This strategy doubles the line potential by making available two systems which, when not working synchronously, work as different and independent technologies.

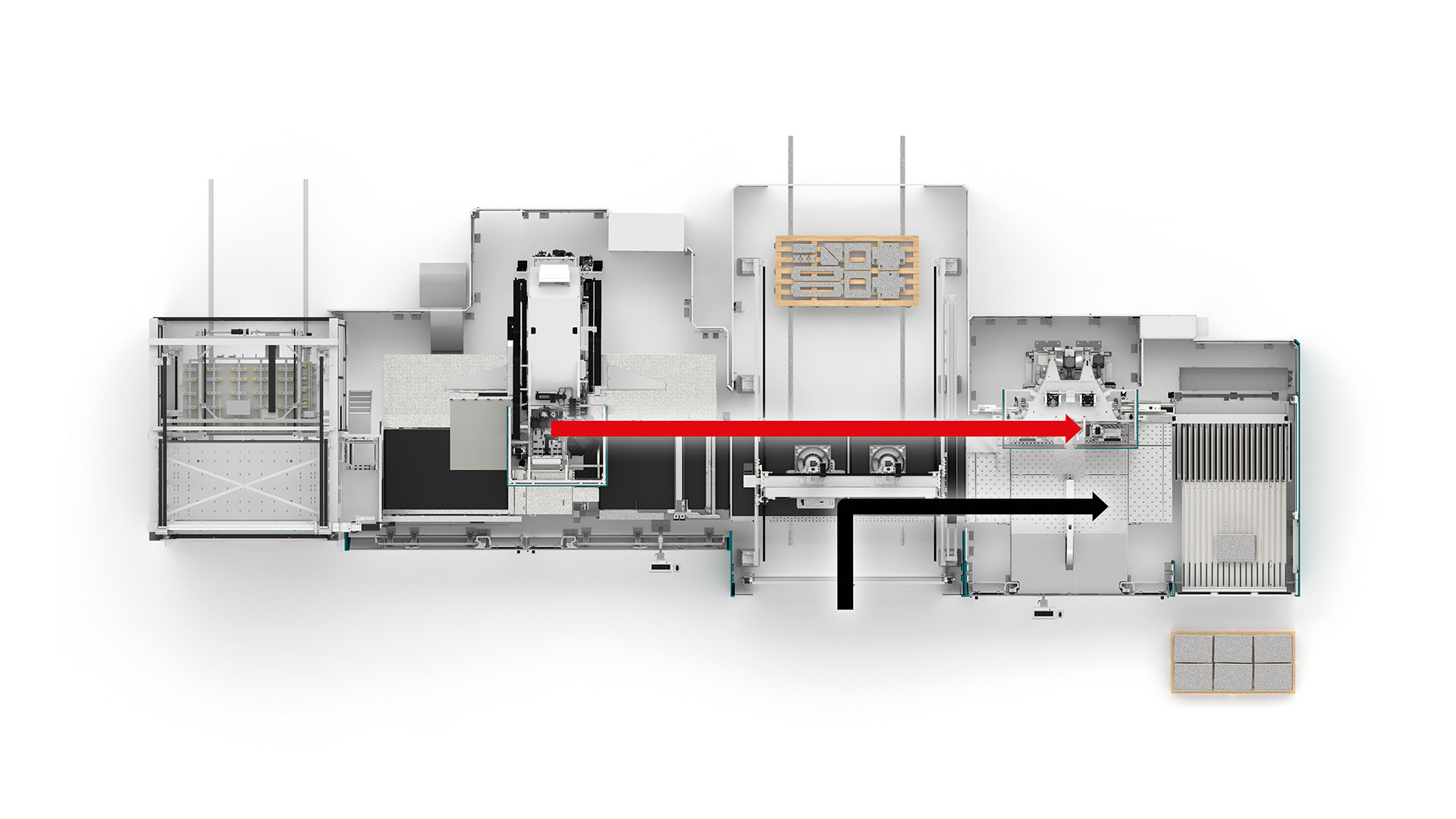

Stack

The stack mode strategy maximizes the S4 productivity. The S4 feeds the P4 but does not wait for the P4 to be available for subsequent parts: it continues to punch and separate the parts, which are unloaded to feed other workstations and the semi-finished part store. As soon as the P4 is available again, the system returns to in line production and the S4 feeds the panel bender once more.

Pack

The pack mode strategy maximizes the P4 productivity. If the P4 is available but the S4 hasn’t completed its jobs, the panel bender is fed by the PCD with already cut parts. As soon as the S4 is ready to send a part to the P4, the pack feeding is automatically stopped to allow the punched part passing through to be bent.

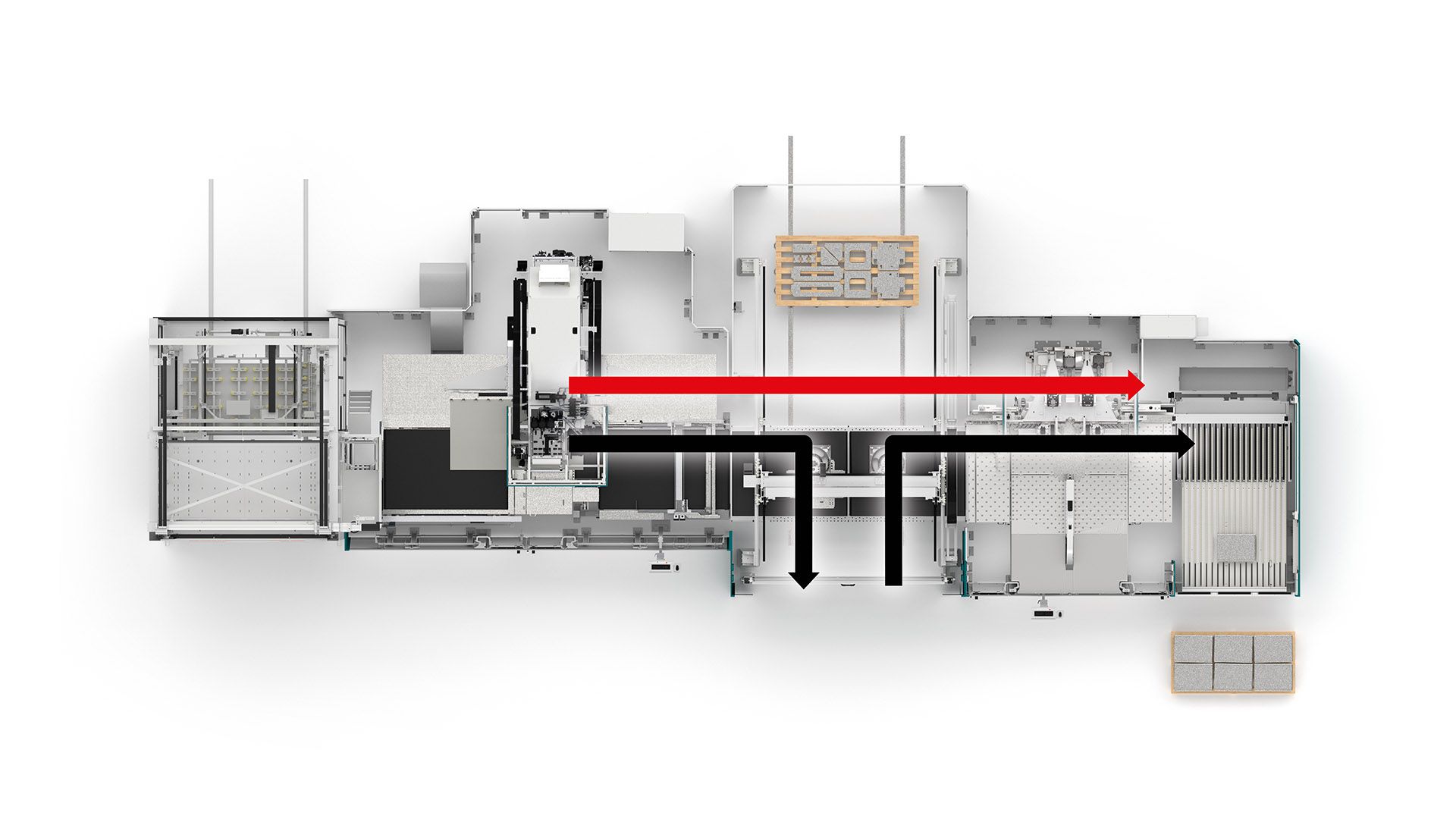

Dynamic

Dynamic buffering assures a truly independent system in terms of balancing. The line is able to independently decide what to do: when the P4 is busy, the parts arriving from the S4 are automatically parked in the waiting position; when the P4 is available and the S4 is not able to feed it, the parts in the waiting position are automatically recovered and produced. The line intelligence automatically manages dynamic buffering: it optimizes the productivity of both machines without adding constraints to the nest programming, giving priority to line jobs, optimizing a specific work flow to facilitate other downstream operations on the line such as assembly. Dynamic buffering requires the MCU automatic sorting device to be placed between the S4 and the P4.

Most frequest sectors and configurations

S4 | P4 | SMD | IA | MCU | ACP | PCD | RIP | SAP | |

| HVAC | ● | ● | ● |

|

| ● |

|

| ● |

| Doors | ● | ● | ● | ● |

| ● |

|

| ● |

| Electrical industry | ● | ● | ● |

| ● |

|

| ● | ● |

| Lifts/elevators | ● | ● | ● | ● |

| ● |

| ● | ● |

| Ho.Re.Ca. | ● | ● | ● | ● |

|

| ● | ● | ● |

| Construction | ● | ● | ● |

| ● |

| ● | ● | ● |

| Subcontracting | ● | ● | ● |

| ● |

| ● | ● | ● |

| Steel furniture | ● | ● | ● |

| ● |

| ● | ● | ● |

Trusted by manufacturers: hear their experience

Løgstrup | Denmark

Løgstrup, a Danish leader in switchboards and modular enclosures, boosted its production with a fully automated Salvagnini line. Equipped also with ACF cornerformers, this S4+P4 ensures precise, weld-free corner forming while minimizing manual work. End-to-end automation and OPS software streamline workflows, enabling Løgstrup to deliver high-quality modular panels for the growing electrical and green energy sectors.

MingYang Electric | China

MingYang New Energy, a leading Chinese manufacturer of intelligent electrical equipment, enhanced its production with a Salvagnini S4+P4 automated line. This smart FMS cut operators from six to two, improved material utilization to nearly 90%, and streamlined workflows for greater efficiency. Backed by reliable support and fast service, this investment strengthened MingYang’s capabilities while reinforcing its commitment to innovation and customer satisfaction.

Henke | Germany

Henke GmbH, a German specialist in sheet metal working, expanded its capabilities with a Salvagnini S4+P4 line. This fully automated system exceeded expectations by combining high speed with low unit costs. With its high level of automation, Henke now produces larger volumes in shorter times while improving cost efficiency.

Wippro | Austria

Wippro GmbH, an Austrian specialist in attic stairs, roof hatches, and wooden doors, has relied on Salvagnini technology since 1998. With its S4+P4 line, integrated with a store tower and stacking robot, the company now punches, bends, and sorts components fully automatically. This highly flexible system enables economical batch size 1 production, boosting efficiency and adaptability.

NAD | Emirates

NAD Group, a leading furniture manufacturer with operations in the UAE and Turkey, transformed its production with a Salvagnini S4+P4 line. This FMS streamlined processes, enabling next-day delivery for custom orders and significantly boosting efficiency. Supported by Salvagnini’s advanced technology and reliable service, NAD Group strengthened its competitiveness and positioned itself for future growth.

Pramac | Spain

Pramac Ibérica, Spanish manufacturer of power generators, enhanced its production with a Salvagnini fully automated S4+P4 line. This FMS increased flexibility, precision, and safety while cutting costs and lead times. As a result, Pramac Ibérica now produces 15% faster and has expanded capacity by 40%.

Intelligent system, constant quality.

Practically everything you ever wanted to know about the S4+P4 line, satisfactorily explained.

It is the ideal OEM solution with highly variable, parametric products or those with non-elementary shapes, as it guarantees the continuous production of kits and batches, whatever their size, minimizing cycle times, semi-finished parts and intermediate handling.

Efficiency, because passing from a traditional layout, with independent punching, cutting and bending stations, to a fully integrated configuration with the S4+P4, increases flexibility and maximizes production capacity. The line drastically reduces semi-finished parts and intermediate handling, while eliminating re-tooling times.

Salvagnini provides a wide range of services to guarantee the efficiency of the S4+P4 line over time, assuring maximum reliability and productivity. The range of services includes multi-level training for programming, using and maintaining the installed systems and exploiting their potential to the full, maintenance contracts, which guarantee maximum efficiency and reliability of your equipment, but also includes advanced services including data-driven analysis and optimization of production flows using the most modern digital instruments.

Production capacity corresponds to the sum of work and losses. The more automation reduces, if not completely eliminates redundant and low-added value activities upstream and downstream of the individual systems, with preparation, feeding and connection functions, the more profitable it is. Over the years, automatic punching and panel bending systems have become extremely quick and productive: the problem of efficiency has shifted to the loading and unloading steps which, increasingly often, become real bottlenecks. In production contexts with low volumes and rapid production changes, connecting automatic loading/unloading devices and intuitive, easy-to-use software, like NEXUS and STORE, is a winning strategy for recovering efficiency and achieving great results.

The S4+P4 line offers high potential for configuration, which may be short, tight, without unloading devices between the S4 and P4. It may be equipped with devices for unloading, stacking and turning parts. It may exploit additional loading devices, positioned between the S4 and P4, and robotized solutions for stacking parts. It may include, upstream and downstream, different workstations for coil feeding, polishing, painting, welding etc. The high configurability of S4+P4 allows it to easily adapt to different production strategies and contexts.

Of course! Salvagnini has always worked to produce solutions with low environmental impacts, guaranteeing maximum operator safety, ergonomic use and resource optimization.

- Reduced energy consumption, using only high-efficiency components.

- Limited compressed air consumption by automations using patented AVC technology. The vacuum is generated only when necessary.

- Consumption monitoring. It is the first step for pro-actively working towards their optimization and reduction.

- Best use of materials and zero waste, exploiting adaptive technologies, proprietary algorithms, closed-chain checks and technological solutions that effectively reduce scrap.

- Optimized timing, with activities proceeding in parallel and in masked time.

- Longer lasting. Each system can be modified, updated or extended over the years, adapting to new strategies or new production needs.

- Recyclable at end-of-life. Each system consists above all of steel mechanical parts and metallic perimeter guards, water painted without organic solvents or coloring agents containing heavy metals.

- It optimizes the factory space, maximizing productivity per m2 of ground used.

- Multi-level training in programming, use, maintenance or design for excellent system usage.

- Wide range of digital interconnection solutions between machinery, with the factory ERP, and with the Salvagnini IoT, eliminating errors, waiting times and malfunctions.

- Guarantee of maximum operator safety, certified by the strictest regulations.

- Simple use, proprietary system management, and programming software optimized for each specific technology.

- Maximum use of the system based on specific solutions for each field of application.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the line. LINKS allows real-time monitoring of the machine’s performance and independent analysis.