Case study

Gatta: the obsession for flexibility

Story courtesy of E. Oldrati and G. Giannangeli/Deformazione

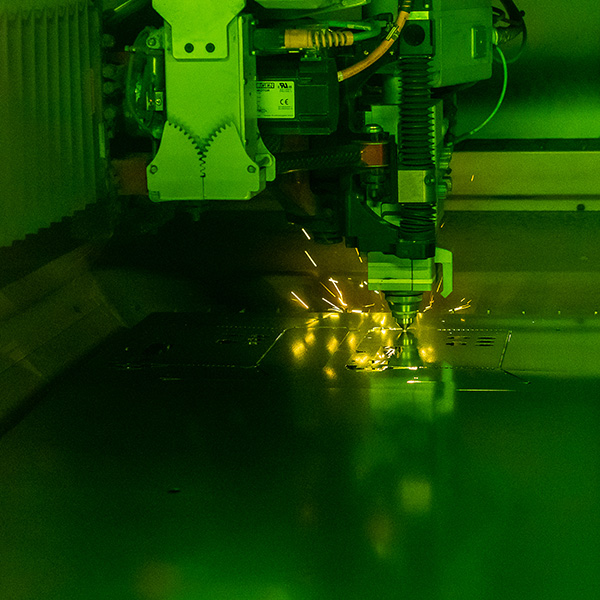

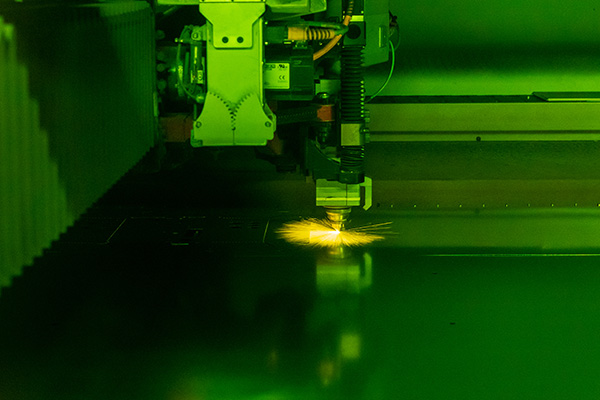

For a modern subcontractor like Gatta srl, working in both light/heavy plate metalworking, extending the autonomy of its systems and increasing flexibility are key to be competitive on the market. To respond to these needs, the Piedmont-based company decided to install a Salvagnini L5 laser cutting system combining high productivity thanks to the 10 kW source, excellent cutting quality and the possibility to automate both loading and unloading as well as the sorting process.

The obsession for flexibility

Highlights

- Gatta

Gatta srl is a metalworking jobshop from Colleretto Giacosa (Turin, Italy). The company was founded in the early 20th century, and later took on an industrial dimension becoming a key supplier for manufacturers of machinery and various kinds of plants. From the 1990s, Gatta Srl, which today employs 70 people, found its final position in the field of sheet metal machining, specializing in both light/heavy plate metalworking. - The context

The company produces electro-welded frames for machine tool and machinery manufacturers, and a range of components in cut, bent and welded sheet metal for a wide range of industries, including electronics, HVAC, telephony, instruments, and cars. All its products are made according to the customer’s designs, in different materials but mainly carbon steel, stainless steel, and aluminum. - The project

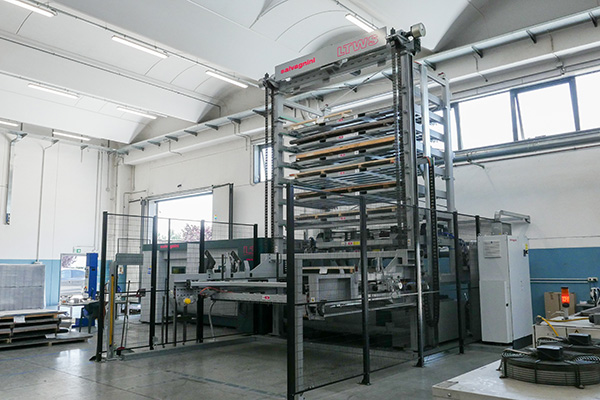

Gatta added to its existing machinery a new laser cutting system with more power and automatic sorting. This choice was particularly strategic, betting on the Salvagnini L5 laser machine with 10 kW power, in the 3-meter version with high automation. To respond to Gatta’s needs, Salvagnini designed and built a system including not only automated loading/unloading with an ADLL device and an MTW - a tailor-made, modular tray-store with several mini-towers, but also an MCU device for automatic sorting with two different unloading bays. - The outcome

"By using the automation on the L5," Marco and Silvia Gatta explain, "we have reduced the time needed to separate the cut parts from the metal sheet and store them before moving onto the next step. The automation downstream of the cutting process allows us to be far more flexible in production, optimizing the industrial process. Finally, the sorting step, with the two unloading bays and the possibility to store the cut parts again without interrupting the process, thus avoiding the intervention of the operator, is one of the added values of this solution."