Case study

Hefa: bent sheet metal for refrigerated cabinets

Story courtesy of F. Finus/blechnet

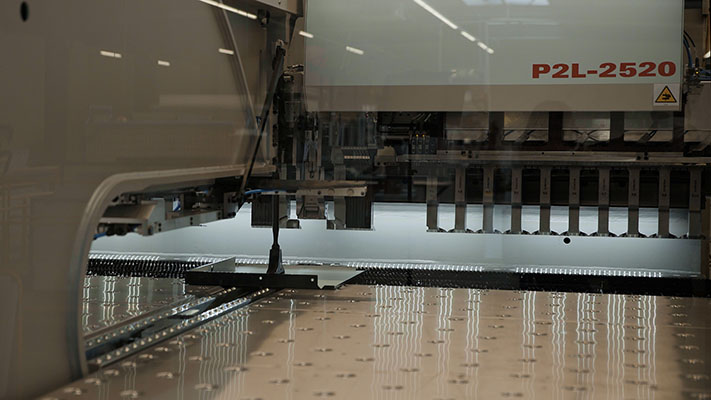

Refrigerated cabinets have a top, a bottom and four side panels. It sounds trivial, but it isn’t. Hefa Kühlmöbel GmbH has even patented it. To process the sheet metal, the company uses a Salvagnini panel bender that has clearly increased output and has made new products possible.

Bent sheet metal for refrigerated cabinets

Highlights

- Hefa

Established in 1984 by Helmut Exner, Hefa Kühlmöbel GmbH, with a team of approx. 70 employees, is holder of a patent that shows its full potential especially in projects such as the ski slopes. Its so-called plug-and-click system for refrigerated cabinets makes it possible to ensure that the main components of the refrigerated cabinets are delivered compactly, so that the customer himself can assemble them simply, safely, and quickly on site. - The context

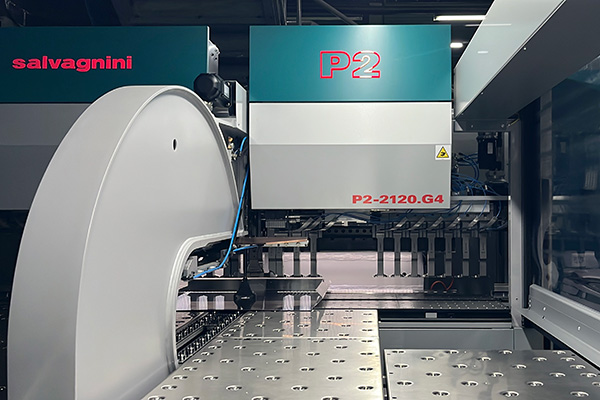

Hefa produces sheet metal panels in-house. Their machinery includes a combined punch-shear for cut-to-size sheets, a conventional press brake and, most recently, a Salvagnini P2 panel bender. - The benefits

“The panel bender opened up completely new possibilities for us and made us much more flexible,” says Simon Garcia, Technical Director at Hefa. He is especially enthusiastic about set-up times elimination: “We have a 10 minutes set-up time for the press brake, but with the panel bender it takes place automatically in 2 seconds.” These time savings have also increased Hefa’s productivity to such an extent that the panel bender is currently not utilized to full capacity. This situation has become topical in the Exner family's considerations about the future. “In addition to producing our own products, we are currently considering using the panel bender for contract manufacturing,” says Bine Exner, Marketing Manager at Hefa.

Check out the case study

Hear what Hefa Kühlmöbel executive team says about the Salvagnini P2 panel bender.