Case study

umdasch: a Salvagnini P4 panel bender in the shopfitting industry

umdasch The Store Makers provides turnkey retail solutions: from wide-ranging market analysis to store branding, from store concept to shop design, from furnishing to installation and digital retail, the shopfitting professionals of umdasch support their customers creating extraordinary shopping experiences. Founded as a little joinery in 1868, today this Amstetten company is part of an international Group with some 20 own branches and approximately 1,500 employees. For its plant in Leibnitz, umdasch has chosen a Salvagnini P4 panel bender.

A Salvagnini P4 panel bender in the shopfitting industry

Highlights

- umdasch

With about 8,800 employees and over 170 sales and logistics facilities on 5 continents, nowadays umdasch boasts three manufacturing sites in Styria: the plant in Gleinstätten, dedicated to the production of wooden furniture, the logistics center in Hasendorf, with around 17.000 m2 of storage capacity, and the factory in Leibnitz, where in about 24.000 m2 of working area Umdasch manufactures different metal goods, from raw to finished products. - The context

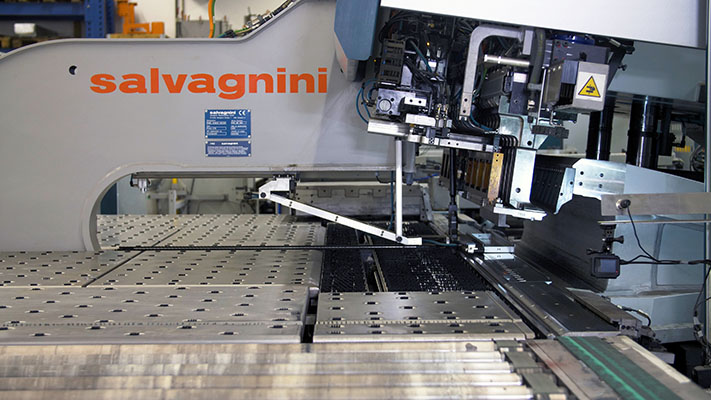

umdasch and Salvagnini have been linked for a long time. In Leibnitz a Salvagnini P4 panel bender, equipped with a PCD conveyor/destacker and a RIP turnover device, is operating since 2015. - The 2nd generation P4

“Before the current system, we already had a Salvagnini P4: we renewed it after approximately 25 years of production. And considering the excellent experience we had with it, when replacing it there was no doubt in choosing again Salvagnini as a partner,” says Michael Ketschler, Sales & Procurement Planning Director at umdasch. “With the P4 we can process our batches very quickly and efficiently, whether they are small or large. The program specifies the length of the tool, and the ABA blankholder automatically adapts itself accordingly.”

Check out the case study

Hear what Michael Ketschler, Sales & Procurement Planning Director at umdasch, says about the Salvagnini P4 panel bender.