Case study

Zhu Cheng: the lean production journey

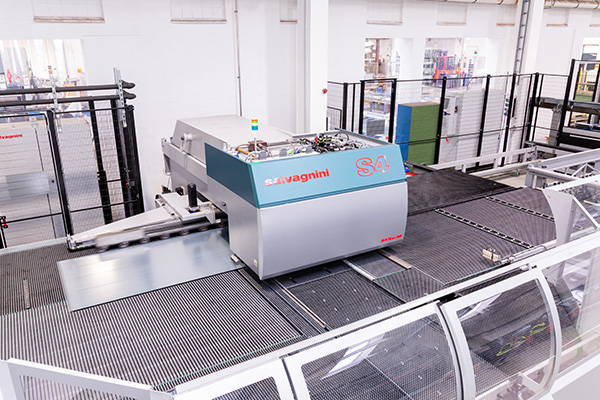

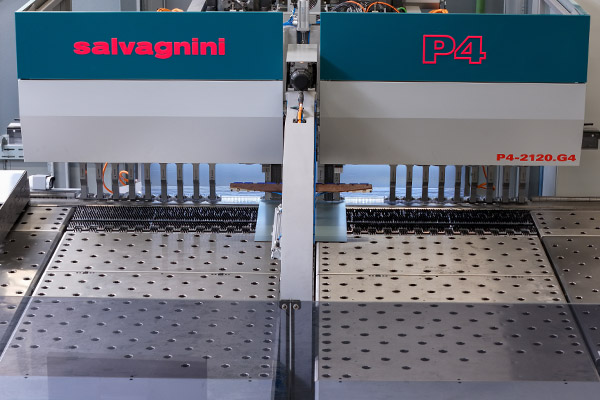

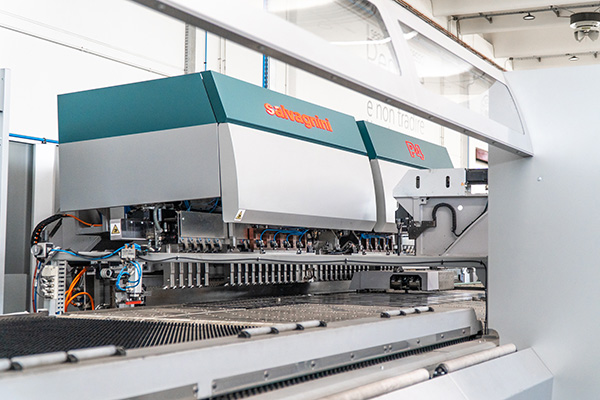

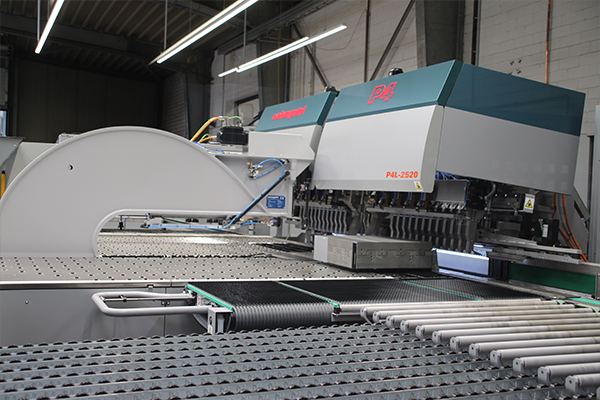

Owning Salvagnini equipment is the ultimate dream of most sheet metal enterprises, because it means gaining access to the high-end sheet metal market. In the 1990s, China Changchun Group got to know Salvagnini in an overseas visit, and in 2000 it introduced the first Salvagnini S4+P4 sheet metal flexible production line. This was also the first Salvagnini flexible production line in China's door industry, and it started a new chapter of flexible manufacturing in this sector.

The lean production journey

Highlights

- Zhu Cheng

Founded in 1998, China Zhu Cheng Group is a technology-oriented manufacturing enterprise. Driven by strong production and research capacity and utilizing advanced production tools and equipment, it has evolved into a modern professional manufacturer, providing a full range of security doors. - The context

All Zhu Cheng door products were manufactured according to the traditional production process, requiring both manual and traditional machinery. It first used turret punch presses to complete the punching processes, and then employed traditional press brakes to complete the bending processes. Loading and unloading required a lot of manpower at the time. - The outcome

The unique multi-press head, universal bending tools and patented program control software of the Salvagnini S4+P4 line allow it to run in a fully automatic and highly integrated way, without the need for re-tooling during the process. This minimizes the risk of errors, and guarantees machining accuracy by maintaining highly consistent quality, whether manufacturing a single product or a variety of products.

Check out the case study

Hear what Zhang XinGen, CEO of Zhu Cheng Group, says about the Salvagnini S4+P4 FMS.