Case study

Fural: flexible panel bender for perfect metal ceilings

Story and pictures courtesy of N. Novotny/Blechtechnik

As a leader in quality and competence for metal ceiling systems, the Fural Group relies on machinery solutions from Salvagnini for processing sheet metal panels in all three of its production facilities in Germany, Switzerland and Austria. At the company’s site in Gmunden (Upper Austria), two automatic P4lean panel benders are being used and are greatly appreciated due to their flexibility and precision.

Flexible panel bender for perfect metal ceilings

Highlights

- Fural

In order to do justice to its own company motto “Perfect metal ceilings” with top production quality, Fural Group relies on a high degree of vertical integration with well-equipped machinery. Currently, a total of five Salvagnini panel benders are in use, distributed among the three plants. - Flexible and fast

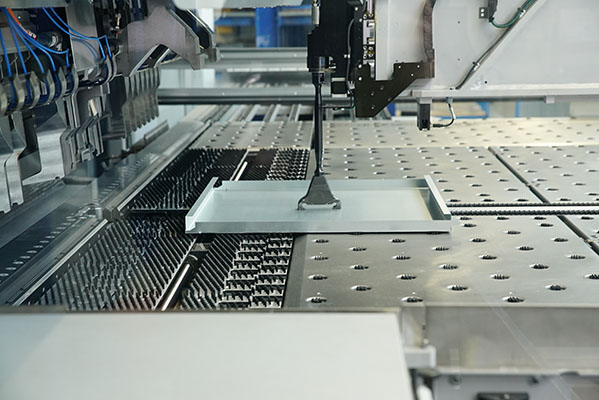

The Gmunden plant is using two state-of-the-art P4 panel bender in combination, to Fural's complete satisfaction. The two machines, with bending lengths of 3,200 and 2,180 mm, are positioned right next to each other, so that for large runs one employee is sufficient for operation. Each panel bender is loaded using the HPT manual positioning table. From there, the machine collects the raw material autonomously. After a fully-automated bending process, the finished part is ready to be unloaded from the second level of the HPT. The operator can use the processing time of approx. 30 seconds to take care of any additional work necessary, such as riveting the corners on the ceiling element, for example. If this is the case, or if batch sizes are too small, an additional machine operator is involved.

Check out the case study

Hear what Christian Demmelhuber, CEO of Fural Systeme in Metall GmbH, says about the P4 panel bender.